Increased Focus on Automation

The Multi Component Injection Moulding Technology Market is benefiting from an increased focus on automation within manufacturing processes. Automation enhances production efficiency, reduces labor costs, and improves product quality, making it an attractive option for manufacturers. The integration of automated systems in multi-component injection moulding allows for precise control over the injection process, leading to consistent and high-quality outputs. As industries strive for operational excellence, the adoption of automated solutions is expected to rise, further driving the demand for multi-component injection moulding technology. This trend suggests a shift towards more advanced manufacturing capabilities that can meet the challenges of modern production.

Growth in Consumer Electronics

The Multi Component Injection Moulding Technology Market is witnessing substantial growth due to the rising demand for consumer electronics. As devices become more compact and multifunctional, manufacturers are increasingly utilizing multi-component injection moulding to create intricate designs that enhance product functionality. This technology allows for the integration of multiple materials, enabling the production of components with varying properties, such as flexibility and rigidity. The consumer electronics sector is projected to expand, with multi-component injection moulding being pivotal in developing innovative products. This trend indicates a shift towards more sophisticated manufacturing processes that cater to evolving consumer preferences.

Emergence of Smart Manufacturing

The Multi Component Injection Moulding Technology Market is poised for growth with the emergence of smart manufacturing practices. The integration of Internet of Things (IoT) technologies and data analytics into manufacturing processes is transforming how products are designed and produced. Multi-component injection moulding is well-suited for smart manufacturing, as it allows for real-time monitoring and optimization of production processes. This capability enhances efficiency and reduces waste, aligning with the goals of modern manufacturing. As industries increasingly adopt smart technologies, the demand for multi-component injection moulding is expected to rise, reflecting a shift towards more intelligent and responsive manufacturing systems.

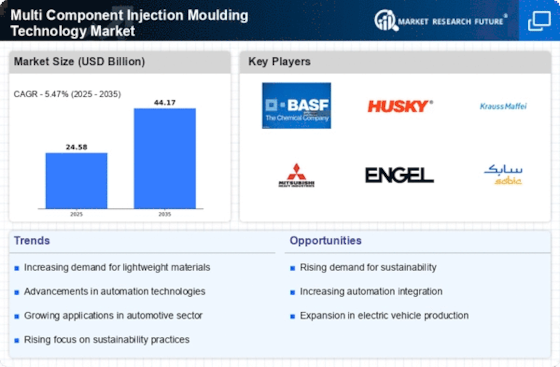

Rising Demand for Lightweight Materials

The Multi Component Injection Moulding Technology Market is experiencing a notable increase in demand for lightweight materials, particularly in sectors such as automotive and aerospace. Manufacturers are increasingly adopting multi-component injection moulding to produce complex parts that are not only lightweight but also durable. This trend is driven by the need for fuel efficiency and reduced emissions, prompting companies to seek innovative solutions. According to industry reports, the lightweight materials market is projected to grow significantly, with multi-component injection moulding playing a crucial role in meeting these requirements. As a result, the technology is becoming a preferred choice for producing components that meet stringent performance standards while minimizing weight.

Regulatory Compliance and Safety Standards

The Multi Component Injection Moulding Technology Market is increasingly influenced by stringent regulatory compliance and safety standards across various sectors. Manufacturers are compelled to adopt advanced technologies that ensure product safety and environmental sustainability. Multi-component injection moulding offers the advantage of producing components that meet these regulatory requirements while maintaining high performance. As industries face growing scrutiny regarding product safety and environmental impact, the demand for technologies that facilitate compliance is likely to rise. This trend indicates a broader movement towards responsible manufacturing practices that align with regulatory expectations.