Cost-Effectiveness

Cost considerations play a pivotal role in the Modular Refineries Market. Modular refineries typically require lower capital investment compared to traditional large-scale refineries. This cost-effectiveness is particularly appealing to emerging markets where financial resources may be limited. The modular approach allows for phased investments, enabling operators to scale operations as demand increases. Furthermore, operational costs are often reduced due to the smaller footprint and streamlined processes of modular refineries. This financial advantage is likely to attract more stakeholders, thereby fostering growth within the modular refinery sector.

Regulatory Support

The Modular Refineries Market benefits from favorable regulatory frameworks that encourage the establishment of smaller, more efficient refining operations. Governments are increasingly recognizing the need for energy independence and security, leading to policies that support modular refinery development. Incentives such as tax breaks and streamlined permitting processes are being introduced to facilitate investment in this sector. As regulatory environments evolve, they are likely to create a conducive atmosphere for modular refineries, enhancing their attractiveness to investors and operators alike.

Rising Energy Demand

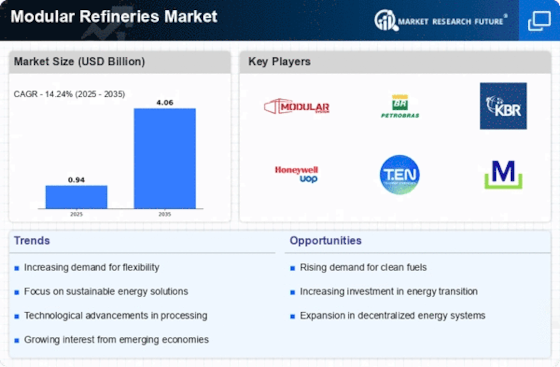

The Modular Refineries Market is experiencing a surge in demand for energy due to increasing industrialization and urbanization. As economies expand, the need for refined petroleum products rises, prompting investments in modular refineries. These facilities offer a flexible solution to meet local energy needs efficiently. According to recent data, the demand for refined products is projected to grow at a compound annual growth rate of approximately 3% over the next five years. This trend indicates that modular refineries, with their ability to be deployed quickly and tailored to specific market requirements, are well-positioned to capitalize on this growing energy demand.

Technological Innovations

Technological advancements are significantly shaping the Modular Refineries Market. Innovations in refining processes, such as advanced catalytic cracking and hydrocracking technologies, are enhancing the efficiency and output of modular refineries. These technologies enable operators to maximize yield while minimizing environmental impact. Moreover, the integration of digital technologies, such as IoT and AI, is streamlining operations and improving decision-making processes. As these technologies continue to evolve, they are expected to further enhance the operational capabilities of modular refineries, making them a more viable option for meeting energy demands.

Environmental Considerations

Environmental sustainability is becoming increasingly critical in the Modular Refineries Market. As concerns over climate change and pollution grow, there is a pressing need for cleaner refining solutions. Modular refineries are often designed with advanced emission control technologies, making them more environmentally friendly compared to traditional refineries. This focus on sustainability not only aligns with global environmental goals but also appeals to consumers and investors who prioritize eco-friendly practices. As regulatory pressures mount, the ability of modular refineries to adapt to stringent environmental standards may provide a competitive edge in the market.