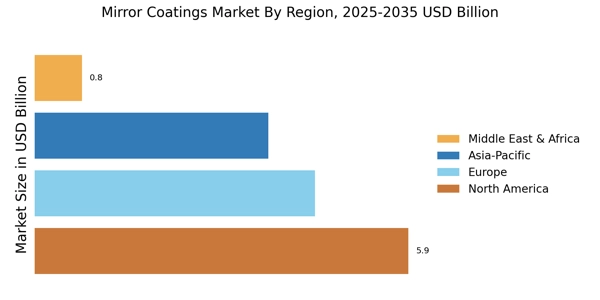

North America : Market Leader in Innovation

North America is the largest market for mirror coatings, holding approximately 40% of the global share. The region's growth is driven by increasing demand in automotive, construction, and electronics sectors, alongside stringent regulations promoting energy efficiency. The U.S. leads this market, followed closely by Canada, as both countries invest in advanced technologies and sustainable practices to enhance product performance and reduce environmental impact. The United States mirror coatings market is driving significant growth in North America, fueled by demand in automotive, construction, and electronics sectors.

The competitive landscape is characterized by key players such as Guardian Glass, 3M, and PPG Industries, which dominate the market with innovative solutions. The presence of these companies fosters a robust ecosystem for research and development, ensuring continuous advancements in mirror coating technologies. Additionally, the region benefits from a well-established supply chain and strong distribution networks, further solidifying its market position.

Europe : Emerging Regulatory Frameworks

Europe is witnessing significant growth in the mirror coatings market, accounting for approximately 30% of the global share. The region's expansion is fueled by increasing environmental regulations and a shift towards sustainable building materials. Countries like Germany and France are at the forefront, implementing policies that encourage the use of energy-efficient products, thus driving demand for advanced mirror coatings that meet these standards. Leading countries in this market include Germany, France, and the UK, where major players like Saint-Gobain and Schott AG are actively innovating. The competitive landscape is marked by a focus on sustainability and technological advancements, with companies investing heavily in R&D to develop eco-friendly products. The presence of regulatory bodies ensures compliance and promotes a culture of innovation, enhancing the overall market dynamics.

Asia-Pacific : Rapidly Growing Market Potential

Asia-Pacific is rapidly emerging as a significant player in the mirror coatings market, holding around 25% of the global share. The region's growth is driven by urbanization, increasing disposable incomes, and a booming construction industry. Countries like China and India are leading this trend, with substantial investments in infrastructure and housing projects that require advanced mirror coatings for aesthetic and functional purposes. Rapid urbanization, infrastructure development, and rising demand from automotive and construction sectors are supporting growth in the India mirror coatings market, making the country a key contributor to regional expansion. Likewise, The Vietnam mirror coatings market is expanding rapidly, supported by rising investments in infrastructure and collaboration between local manufacturers and global players.

China stands out as the largest market, followed by India, where local manufacturers are increasingly collaborating with global players to enhance product offerings. The competitive landscape is evolving, with companies like Nippon Sheet Glass and Avery Dennison making strides in innovation. The region's market is characterized by a mix of established players and emerging startups, fostering a dynamic environment for growth and development.

Middle East and Africa : Untapped Market Opportunities

The Middle East and Africa region is gradually emerging in the mirror coatings market, currently holding about 5% of the global share. The growth is primarily driven by increasing investments in infrastructure and real estate, particularly in the Gulf Cooperation Council (GCC) countries. Investments in infrastructure and real estate are driving growth in the Saudi Arabia mirror coatings market, positioning the country as a key contributor to the region’s overall market expansion. As urbanization accelerates, there is a rising demand for high-quality mirror coatings in both residential and commercial sectors, supported by government initiatives to enhance building standards.

Leading countries in this region include the UAE and South Africa, where local and international players are beginning to establish a foothold. The UAE mirror coatings market is experiencing significant growth, driven by increasing investments in commercial and residential infrastructure projects. The competitive landscape is still developing, with opportunities for growth as more companies recognize the potential of this market. Key players are focusing on establishing partnerships and expanding their product lines to cater to the unique needs of this diverse region.