Rising Demand for Methanol

The Global Methanol Catalyst Market Industry experiences a surge in demand for methanol, driven by its applications in various sectors including automotive, energy, and chemicals. As of 2024, the market is projected to reach 8 USD Billion, reflecting a growing preference for methanol as a cleaner alternative to traditional fuels. This shift is largely attributed to the increasing focus on sustainability and reducing carbon emissions. Moreover, the anticipated growth in methanol production facilities worldwide further supports this trend, indicating a robust future for methanol catalysts in facilitating efficient production processes.

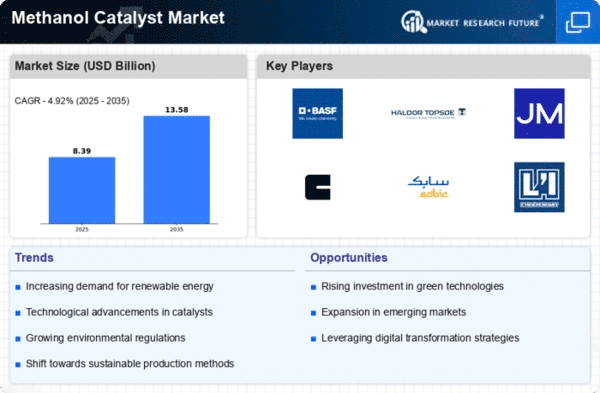

Market Trends and Projections

The Global Methanol Catalyst Market Industry is characterized by evolving trends and projections that indicate a promising future. The market is expected to grow from 8 USD Billion in 2024 to 13.6 USD Billion by 2035, reflecting a compound annual growth rate of 4.92% from 2025 to 2035. This growth trajectory is influenced by various factors, including increasing methanol production, technological advancements, and supportive government policies. The industry is likely to witness a diversification of catalyst technologies, catering to the specific needs of different production processes, thereby enhancing overall efficiency and sustainability.

Growth in the Chemical Industry

The chemical industry serves as a significant driver for the Global Methanol Catalyst Market Industry, as methanol is a key feedstock for various chemical processes. The increasing production of formaldehyde, acetic acid, and other derivatives from methanol is propelling the demand for effective catalysts. As the global chemical sector expands, particularly in emerging economies, the need for efficient methanol catalysts becomes more pronounced. This growth is expected to contribute to the overall market dynamics, with a notable increase in investments directed towards catalyst development and production technologies, thereby enhancing the industry's competitive landscape.

Technological Advancements in Catalysts

Technological innovations play a pivotal role in the Global Methanol Catalyst Market Industry, enhancing the efficiency and effectiveness of methanol production. Recent advancements in catalyst formulations and processes have led to improved yields and reduced operational costs. For instance, the development of novel catalysts that operate at lower temperatures and pressures has the potential to revolutionize methanol synthesis. These innovations not only optimize production but also align with global sustainability goals, thereby attracting investments and fostering growth in the market. As a result, the industry is likely to witness a compound annual growth rate of 4.92% from 2025 to 2035.

Government Regulations Favoring Clean Fuels

The Global Methanol Catalyst Market Industry benefits from stringent government regulations aimed at promoting cleaner fuels and reducing greenhouse gas emissions. Many countries are implementing policies that encourage the use of methanol as a renewable energy source, which in turn drives the demand for methanol catalysts. For example, various nations are setting ambitious targets for reducing carbon footprints, thereby creating a favorable environment for methanol production. This regulatory support not only enhances market growth but also positions methanol as a viable alternative in the global energy landscape, with projections indicating a market value of 13.6 USD Billion by 2035.

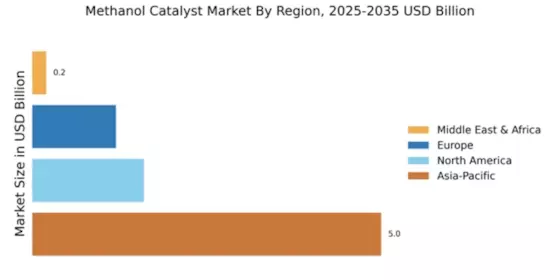

Emerging Markets and Investment Opportunities

Emerging markets present substantial opportunities for the Global Methanol Catalyst Market Industry, as industrialization and urbanization drive the demand for methanol. Countries in Asia-Pacific and Latin America are witnessing rapid economic growth, leading to increased investments in methanol production facilities. This trend is likely to stimulate the demand for advanced catalysts that can optimize production processes. Furthermore, the global shift towards sustainable energy solutions encourages foreign investments in these regions, fostering a conducive environment for market expansion. As a result, the industry is poised for growth, with significant potential for innovation and development in catalyst technologies.