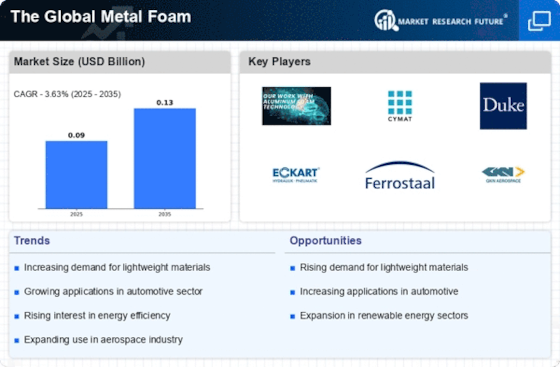

Top Industry Leaders in the Metal Foam Market

While traditional metals evoke images of solidity and weight, the world of metal foam rewrites the rules. This innovative material, boasting the strength of its metallic ancestors combined with the lightness of air, is revolutionizing industries from aerospace to medical technology. The global metal foam market is a battlefield where established players and nimble startups clash for a piece of this lightweight future. Let's delve into the strategies driving success, the factors governing market share, and the recent developments propelling the metal foam revolution.

While traditional metals evoke images of solidity and weight, the world of metal foam rewrites the rules. This innovative material, boasting the strength of its metallic ancestors combined with the lightness of air, is revolutionizing industries from aerospace to medical technology. The global metal foam market is a battlefield where established players and nimble startups clash for a piece of this lightweight future. Let's delve into the strategies driving success, the factors governing market share, and the recent developments propelling the metal foam revolution.

Strategies Shaping a Lighter Footprint:

Product Diversification: Beyond the classic aluminum and nickel foams, companies like Elkem and Exco Technologies are developing a diverse range of foams with tailored properties. This includes options like copper foams for heat exchangers, magnesium foams for lightweight vehicles, and biocompatible titanium foams for medical implants.

Sustainability Focus: Environmental consciousness is finding its way into the metal foam world. Companies like RECA are pioneering closed-loop production processes, minimizing waste and recycling scrap metal back into new foams. This resonates with eco-conscious consumers and aligns with industry regulations.

Technological Innovation: From laser sintering to additive manufacturing, the metal foam landscape is brimming with innovation. Companies like Heraeus are pushing the boundaries of foam density, pore size, and intricate geometries, unlocking new applications and performance possibilities.

Strategic Partnerships and Collaborations: Collaboration is key in navigating the complex world of metal foam development and commercialization. Companies like Schunk are working with research institutions, metal suppliers, and end-user industries to optimize production processes, share expertise, and accelerate market adoption.

Cost-Effectiveness and Scalability: While offering superior properties, metal foams currently face cost challenges. Companies like Luxfoam are investing in research and development to improve production efficiency and reduce costs, making metal foams more competitive and accessible for a wider range of applications.

Factors Influencing Market Share:

-

Performance and Functionality: Metal foams' unique combination of strength, lightness, thermal conductivity, and sound absorption must meet specific application requirements. Companies with foams offering tailored properties gain a competitive edge. -

Cost-Effectiveness and Scalability: Metal foams need to be cost-competitive with traditional materials for wider adoption. Companies with efficient production processes and economies of scale hold an advantage. -

Regulations and Industry Standards: Stringent safety regulations and industry standards for specific applications, like in aircraft or medical devices, can impact market penetration. Companies complying with these standards gain access to valuable markets. -

Technical Support and Service: Integrating metal foams into existing designs and manufacturing processes requires expertise. Companies offering comprehensive technical support and design assistance attract manufacturers seeking to incorporate this innovative material. -

Regional Market Dynamics: Demand for metal foams varies across regions. Developed economies with stricter regulations and advanced manufacturing industries remain dominant, but Asia-Pacific is expected to witness significant growth due to its rapid infrastructure development and increasing industrial automation.

Key Companies in the metal foam market include

ERG Aerospace Corporation (US)

Aluminum King Co. Ltd (China)

CYMAT Technologies Ltd. (Canada)

Alantum (South Korea)

Ultramet (US)

Mott Corporation (US)

Mayser GmbH & Co. KG (Germany)

Liaoning Rontec Advanced Material Technology Co. Ltd. (China)

Shanxi Putai Aluminum Foam Manufacturing Co. Ltd. (China)

Recent Developments:

-

August 2023: Elkem unveils a new magnesium foam with exceptional fire resistance, targeting fireproofing applications in buildings and transportation. -

September 2023: The International Space Station announces the use of 3D-printed copper heat exchangers made from metal foam, showcasing its potential for space exploration. -

October 2023: Exco Technologies partners with a leading medical device manufacturer to develop novel biocompatible titanium foams for orthopedic implants. -

November 2023: RECA receives an award for its sustainable metal foam production process, emphasizing the growing importance of environmental responsibility in the industry. -

December 2023: Luxfoam announces a breakthrough in scaling up its production process, significantly reducing the cost of aluminum foams and enhancing market accessibility.