Rising Demand in Automotive Sector

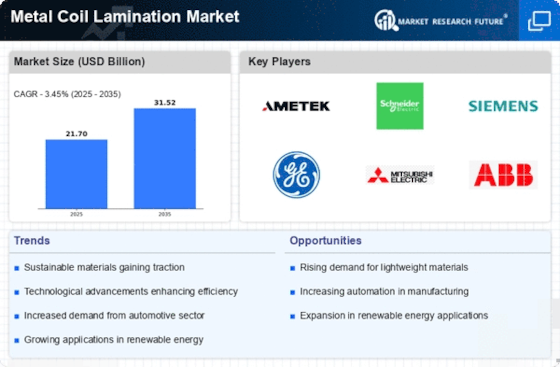

The automotive sector is experiencing a notable increase in demand for lightweight and durable materials, which is likely to drive the Metal Coil Lamination Market. As manufacturers seek to enhance fuel efficiency and reduce emissions, the use of laminated metal coils in vehicle production appears to be a viable solution. Reports indicate that the automotive industry accounts for a substantial portion of the overall metal coil consumption, with projections suggesting a growth rate of approximately 4% annually. This trend indicates a robust market for laminated metal products, as they offer superior performance characteristics compared to traditional materials. Consequently, the Metal Coil Lamination Market is poised to benefit from this rising demand, as automotive manufacturers increasingly prioritize innovative materials to meet regulatory standards and consumer expectations.

Increasing Focus on Energy Efficiency

The growing emphasis on energy efficiency across various industries is influencing the Metal Coil Lamination Market. As companies seek to reduce operational costs and comply with environmental regulations, the demand for energy-efficient materials is on the rise. Laminated metal coils are recognized for their superior thermal and electrical conductivity, making them ideal for applications that require high efficiency. Reports suggest that industries such as HVAC and industrial machinery are increasingly adopting these materials to enhance performance and reduce energy consumption. This trend indicates a promising outlook for the Metal Coil Lamination Market, as energy efficiency becomes a critical factor in material selection and product design.

Growth in Renewable Energy Applications

The shift towards renewable energy sources is creating new opportunities for the Metal Coil Lamination Market. Laminated metal coils are essential components in the manufacturing of transformers and other electrical equipment used in wind and solar energy systems. As the world moves towards sustainable energy solutions, the demand for efficient and reliable electrical components is expected to rise. Market analysis suggests that the renewable energy sector could see an annual growth rate of around 6%, which would significantly impact the demand for laminated metal products. This growth is indicative of a broader trend towards sustainability, where the Metal Coil Lamination Market plays a crucial role in supporting the infrastructure needed for renewable energy technologies.

Expansion of Electrical and Electronics Sector

The electrical and electronics sector is undergoing rapid expansion, which is likely to bolster the Metal Coil Lamination Market. With the increasing demand for consumer electronics, appliances, and industrial equipment, laminated metal coils are becoming essential for various applications, including motors, transformers, and circuit boards. Market data indicates that the electronics industry is projected to grow at a rate of approximately 5% annually, further driving the need for high-quality laminated materials. This growth presents a significant opportunity for the Metal Coil Lamination Market, as manufacturers strive to meet the rising demand for efficient and reliable components in the electrical and electronics sector.

Technological Innovations in Manufacturing Processes

Technological advancements in manufacturing processes are transforming the Metal Coil Lamination Market. Innovations such as advanced coating techniques and automated production lines are enhancing the efficiency and quality of laminated metal products. These technologies not only reduce production costs but also improve the performance characteristics of the final products. For instance, the introduction of high-speed lamination processes has been shown to increase output while maintaining stringent quality standards. As manufacturers adopt these technologies, the Metal Coil Lamination Market is likely to experience increased competitiveness and growth. Furthermore, the integration of smart manufacturing practices may lead to more customized solutions, catering to specific industry needs.