Increased Focus on Equipment Longevity

In the Lubricant Anti-Wear Agents Market, there is a growing emphasis on extending the lifespan of machinery and equipment. Industries are increasingly recognizing that the cost of equipment failure can be substantial, leading to downtime and lost productivity. As a result, the integration of anti-wear agents in lubricants is becoming a standard practice to mitigate wear and tear. This focus on equipment longevity is particularly pronounced in sectors such as manufacturing and construction, where machinery operates under extreme conditions. Data suggests that the use of advanced anti-wear agents can reduce maintenance costs by up to 30%, making them an attractive investment for companies aiming to enhance operational efficiency. Thus, the demand for high-quality anti-wear agents is expected to rise as industries prioritize the durability and reliability of their equipment.

Rising Demand for High-Performance Lubricants

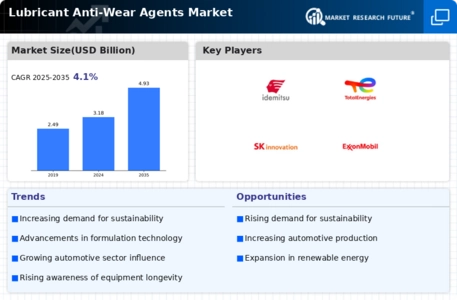

The Lubricant Anti-Wear Agents Market is experiencing a notable increase in demand for high-performance lubricants across various sectors, including automotive, industrial, and aerospace. This trend is driven by the need for enhanced efficiency and longevity of machinery and engines. As manufacturers strive to meet stringent performance standards, the incorporation of anti-wear agents becomes essential. According to recent data, the market for high-performance lubricants is projected to grow at a compound annual growth rate of approximately 5% over the next few years. This growth is indicative of a broader shift towards advanced formulations that not only improve performance but also reduce wear and tear, thereby extending the lifespan of equipment. Consequently, the demand for effective anti-wear agents is likely to rise, positioning them as a critical component in the lubricant formulation process.

Growing Automotive Sector and Electric Vehicles

The Lubricant Anti-Wear Agents Market is significantly influenced by the growth of the automotive sector, particularly with the rise of electric vehicles (EVs). As the automotive industry evolves, there is an increasing need for lubricants that can withstand the unique demands of electric drivetrains. Anti-wear agents play a crucial role in ensuring the efficiency and reliability of these systems. The Lubricant Anti-Wear Agents is projected to reach USD 80 billion by 2026, with a substantial portion attributed to the demand for advanced anti-wear agents. This growth is indicative of a broader trend towards innovation in lubricant formulations that cater to the specific requirements of modern vehicles. As the automotive sector continues to expand, the demand for specialized anti-wear agents is expected to follow suit, further driving market growth.

Regulatory Pressures for Environmental Compliance

In the Lubricant Anti-Wear Agents Market, regulatory pressures are increasingly shaping the landscape of lubricant formulations. Governments and regulatory bodies are implementing stringent environmental regulations aimed at reducing the ecological impact of lubricants. This has prompted manufacturers to seek out anti-wear agents that not only meet performance criteria but also comply with environmental standards. The shift towards biodegradable and less toxic anti-wear agents is becoming more pronounced, as companies strive to align with sustainability goals. Data indicates that the market for environmentally friendly lubricants is expected to grow at a rate of 6% annually, driven by these regulatory changes. Consequently, the demand for compliant anti-wear agents is likely to rise, as manufacturers adapt their formulations to meet evolving regulations.

Technological Innovations in Lubricant Formulations

The Lubricant Anti-Wear Agents Market is witnessing a surge in technological innovations that enhance the performance of lubricants. Advances in chemical engineering and material science have led to the development of new anti-wear agents that offer superior protection against friction and wear. These innovations not only improve the efficiency of lubricants but also contribute to sustainability by reducing the need for frequent oil changes. For instance, the introduction of nanotechnology in lubricant formulations has shown promising results in enhancing the anti-wear properties of lubricants. As industries continue to adopt these cutting-edge technologies, the demand for innovative anti-wear agents is likely to increase. Market analysts project that the segment of technologically advanced lubricants will grow significantly, reflecting the industry's shift towards more efficient and environmentally friendly solutions.

Leave a Comment