Regulatory Compliance

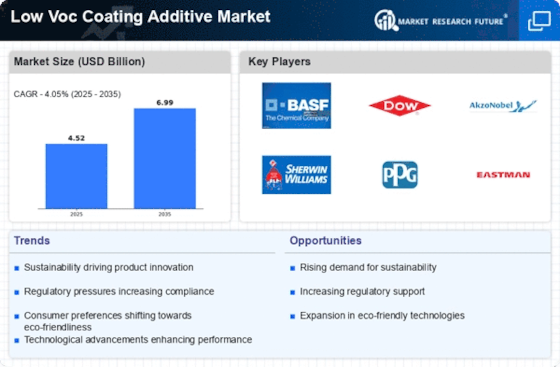

The Low Voc Coating Additive Market is experiencing a surge in demand due to stringent regulations aimed at reducing volatile organic compounds in coatings. Governments across various regions have implemented laws that limit the VOC content in paints and coatings, compelling manufacturers to adopt low VOC alternatives. This regulatory landscape not only drives innovation but also encourages companies to invest in research and development of compliant products. As a result, the market for low VOC coating additives is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 5% in the coming years. Compliance with these regulations is not merely a legal obligation; it is increasingly viewed as a competitive advantage in the marketplace.

Technological Innovations

Technological advancements play a crucial role in shaping the Low Voc Coating Additive Market. Innovations in formulation chemistry and application techniques have led to the development of more effective low VOC additives that do not compromise on performance. For instance, advancements in polymer technology have enabled the creation of coatings that exhibit superior durability and aesthetic appeal while maintaining low VOC levels. Furthermore, the integration of digital technologies in manufacturing processes is streamlining production and enhancing product quality. As these technologies continue to evolve, they are expected to open new avenues for growth within the low VOC segment, potentially increasing market penetration and expanding the range of applications for these additives.

Sustainability Initiatives

The increasing emphasis on sustainability is a significant driver for the Low Voc Coating Additive Market. Companies are increasingly adopting sustainable practices in their operations, which includes the use of low VOC additives in their products. This shift is not only driven by regulatory pressures but also by consumer expectations for environmentally friendly products. Many manufacturers are now prioritizing sustainability in their product development strategies, leading to a rise in the availability of low VOC coatings. Market analysis suggests that the sustainability trend could lead to a doubling of the market size for low VOC additives within the next decade, as more industries recognize the importance of reducing their environmental footprint.

Consumer Awareness and Demand

There is a growing awareness among consumers regarding the health and environmental impacts of traditional coatings, which is positively influencing the Low Voc Coating Additive Market. As consumers become more informed about the benefits of low VOC products, their preferences are shifting towards safer and more sustainable options. This trend is particularly evident in residential and commercial sectors, where end-users are actively seeking low VOC alternatives to minimize indoor air pollution. Market data indicates that the demand for low VOC coatings has increased by approximately 30% over the last few years, reflecting a significant shift in consumer behavior. This heightened demand is likely to propel manufacturers to expand their offerings in the low VOC segment, further driving market growth.

Market Expansion Opportunities

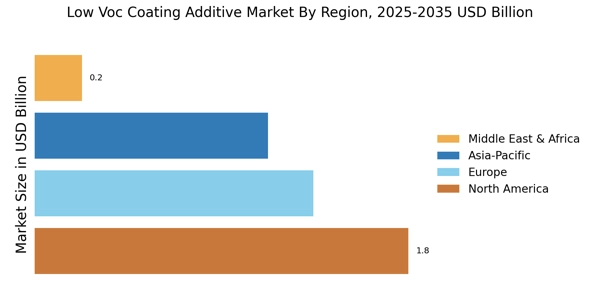

The Low Voc Coating Additive Market is poised for expansion as new applications and markets emerge. Industries such as automotive, construction, and furniture are increasingly adopting low VOC coatings due to their environmental benefits and compliance with regulations. This diversification of applications is likely to create new opportunities for manufacturers and suppliers in the low VOC segment. Additionally, emerging markets are beginning to recognize the importance of low VOC products, which could further drive demand. Market forecasts indicate that the expansion into these new sectors may result in a substantial increase in revenue for companies specializing in low VOC additives, potentially leading to a more competitive landscape.