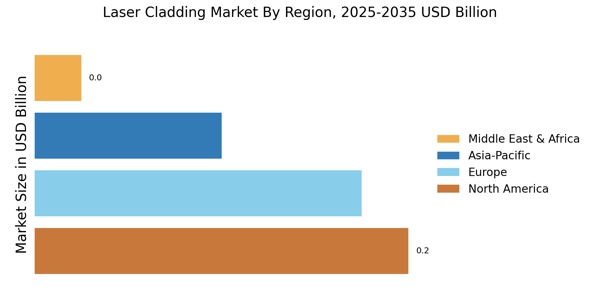

By region, the study provides market insights into North America, Europe, Asia-Pacific and Rest of the World. In 2022, Europe dominated the laser cladding industry, with approximately 45.80% of global revenue due to increasing demand for laser cladding technology in the mechanical engineering and automotive industries in this region's countries, particularly the United Kingdom, Germany, and France Europe is a key manufacturing location for companies such as Audi AG, Volkswagen Group, Fiat Chrysler Automobiles NV, and others. According to the European Automobile Manufacturers Association (ACEA), commercial vehicle manufacturing in Europe will increase by 4.9% in 2021 over the previous year.

For Instance, in 2021, 13.7 million light motor vehicles were registered in Europe. Specific part development and optimization in the automobile sector have become crucial challenges. The use of laser cladding technology increases the cycle life of critical automotive components, making it popular in the automobile sector.

Further, the major countries studied in the market report are The U.S, Canada, Germany, France, UK, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil.

The Asia Pacific laser cladding market is expected to be the fastest-growing market during the forecast period, owing to increased expenditures in laser cladding technology and the development of laser cladding applications by numerous enterprises throughout the region, particularly in India, China, South Korea, and Japan. Furthermore, the growing automotive and aerospace sectors significantly need laser cladding in this region. China is one of the world's top car producers. Total car sales in China are predicted to reach 27.5 million units in 2022, according to the China Association of Automobile Manufacturers (CAAM).

Additionally, increased expansion of the country's automotive industry is predicted to fuel market revenue growth. Further, the China laser cladding market held the largest market share, and the India laser cladding market was the fastest-growing market in the region.

North America laser cladding market is expected to grow at the fastest CAGR due to the significant demand for laser cladding in the aerospace, defense, and semiconductor sectors in nations around this area, particularly in the United States and Canada. The overall commercial aircraft fleet in the United States is estimated to reach 8,270 by 2037, according to the Federal Aviation Administration (FAA). The US president signed the National Defense Authorization Act (NDAA) in December 2021, approving USD 768.2 billion in military spending year 2022, including a 2.7% pay raise for service members.

The country's expanding aerospace and military sectors will likely fuel market revenue growth. Further, the US laser cladding market held the largest market share, and the Canada laser cladding market was the fastest-growing market in the region.