Top Industry Leaders in the Industrial Robotics Market

The Competitive Landscape of the Industrial Robotics Market

Across humming factories echoing with the clang of metal and the whir of gears, beneath sun-scorched roofs where molten metal dances, and behind sterile walls where precision reigns supreme, a silent conductor orchestrates the dance of steel and silicon – the Industrial Robotics Market. This dynamic industry pulsates with the competitive energy of players vying for control over these tireless mechanical maestros of productivity. Unveiling the strategies, crucial factors, and overall landscape of this intricate market is vital for navigating its currents and securing a leading position.

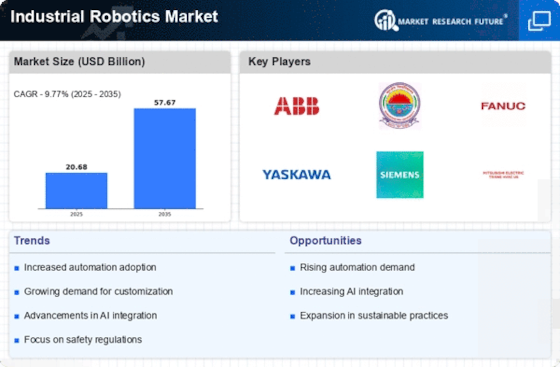

Some of the Industrial Robotics companies listed below:

- ABB

- FANUC Corporation

- Yaskawa Electric Corporation

- MRK-Systeme GmbH

- Epson

- Mitsubishi Electric Corporation

- Comau SpA

- DENSO Corporation

- Kawasaki Heavy Industries, Ltd.

- Omron Corporation

- KUKA AG

- Hirata Corporation

- Toshiba Machine Co. Ltd

Strategies Adopted by Leaders:

- Technological Prowess: ABB and Fanuc lead the charge with advanced robot designs boasting superior payload capacity, speed, and precision, catering to demanding tasks across diverse industries like automotive, electronics, and aerospace.

- Vertical Specialization: Yaskawa Electric and Kawasaki Robotics focus on specific segments like welding robots or collaborative robots for human-robot interaction, achieving unmatched expertise and tailored solutions within their chosen domains.

- Software and Ecosystem Development: Companies like Siemens and KUKA offer comprehensive software suites for robot programming, simulation, and integration with factory automation systems, creating a connected ecosystem for efficient production processes.

- Artificial Intelligence and Machine Learning Integration: Leaders like Kuka and Universal Robots invest heavily in AI-powered robots capable of self-learning, adaptive path planning, and real-time optimization, pushing the boundaries of automation and productivity.

- Partnerships and Collaboration: Open standards and interoperability are key, with players like the Robotics Industry Association (RIA) forging collaborations to ensure robot compatibility and expand market reach.

Critical Factors for Market Share Analysis:

- Robot Capabilities and Performance: Companies offering robots with higher payload capacity, faster cycle times, and greater operational accuracy command premium prices and secure market share by optimizing production lines and minimizing downtime.

- Flexibility and Adaptability: Robots capable of handling diverse tasks, reprogramming on the fly, and integrating seamlessly into existing production lines are crucial for agile manufacturing and responding to changing market demands.

- Safety and Compliance: Robust safety features, user-friendly interfaces, and adherence to stringent safety regulations for human-robot collaboration are essential for ensuring worker safety and meeting legal requirements.

- Total Cost of Ownership (TCO): Balancing upfront costs with factors like system longevity, maintenance requirements, and software updates helps companies choose cost-effective solutions maximizing long-term profitability.

- Service and Support Infrastructure: Offering comprehensive installation, training, maintenance, and repair services provides an additional revenue stream and strengthens customer relationships.

New and Emerging Companies:

- Startups like Boston Dynamics and Agility Robotics: These innovators focus on developing next-generation legged robots capable of navigating complex terrain and interacting with the environment, opening doors for automation in new sectors like construction and logistics.

- Academia and Research Labs: Stanford University's Center for Robot and Sensor Systems and MIT's Computer Science and Artificial Intelligence Laboratory explore disruptive technologies like soft robotics, bio-inspired control algorithms, and human-robot co-working platforms, shaping the future of industrial automation.

- Material Science Companies: DuPont and 3M invest heavily in R&D for lightweight, high-strength materials and advanced sensors, enabling the development of more efficient, agile, and durable robots.

Latest Company Updates:

Oct.25, 2023- Mitsubishi Electric announced that it has secured ESD certification for its industrial robot portfolio. The certification covers a range of MELFA FR horizontal and vertical industrial robots with a maximum payload of 20kg and the RV-5AS-D-ESD industrial collaborative robot. The certification approves the MELFA ESD range for use in various complex production environments where the presence of ESD could cause significant damage to the assembled components.

Oct.18, 2023- Nvidia announced that it is working on enhancing industrial robotics with on-device generative AI features. The company has begun augmenting its industrial and robotics Jetson hardware platform with on-edge generative AI features that operate within a device rather than requiring communications with the cloud. Nvidia claims that the updates will allow its customers across sectors like manufacturing, logistics, and healthcare to more easily adopt emerging generative AI capabilities that promise to boost automation.

Oct.11, 2023- Neuromeka USA, Inc., a collaborative robotics company, announced signing an MoU with KEBA (Austria), a global robotics and industrial automation solutions company, for the joint development of industrial robots. Through this agreement, these companies will collaborate to jointly promote the development of industrial robotic systems, the exploration of automation processes in industrial settings, and the pursuit of new business ventures.

July 21, 2023- Ati Motors, an autonomous industrial robots startup, announced the closing of its new funding round of $10.85 million. Funding will fuel expansion into new markets and industries. The Series A round will help Ati Motors implement plans to expand into Southeast Asia, Japan, the US, and Europe markets and explore opportunities across the chemicals, pharmaceuticals, maritime, and injection molding sectors. Ati Motors will also continue to invest in R&D to launch new products and capabilities in the market.