Top Industry Leaders in the Industrial Microscope Market

The Competitive Landscape of the Industrial Microscope Market

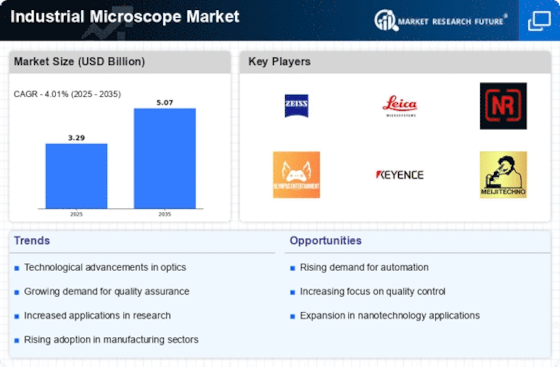

The industrial microscope market, once relegated to dusty labs and niche applications, has blossomed into a vibrant arena teeming with innovation. These powerful lenses, peering into the minutiae of materials and processes, empower industries from aerospace to electronics, ensuring quality control, optimizing production, and propelling scientific advancements. Navigating this dynamic landscape requires a keen understanding of the competitive dynamics, adopted strategies, key players, and emerging trends shaping this microscopic domain.

Some of the Industrial Microscope companies listed below:

- Nikon Corporation

- Carl Zeiss AG

- Olympus Corporation.

- Leica Microsystems

- Bruker Corporation

- JEOL LTD

- Hitachi

- Thermo Fisher Scientific

- Oxford Instruments Plc

- Radical Scientific Equipments Pvt. Ltd.

Strategies Adopted by Leaders:

- Embracing Innovation and Cutting-Edge Technologies: Investing in R&D to integrate novel advancements like artificial intelligence for automated image analysis, laser-based inspection techniques, or advanced image-stitching algorithms for panoramic views can differentiate solutions and cater to evolving user needs.

- Prioritizing User Education and Training: Providing comprehensive training resources, educational workshops, and technical support ensures users leverage the full potential of the microscopes and fosters ongoing customer satisfaction.

- Partnerships and Ecosystem Building: Collaborating with equipment manufacturers, software developers, and industry associations expands reach, offers complete solutions, and strengthens brand presence.

- Focus on Automation and Integration: Developing automated microscopy systems with robotic arms, conveyor belts, and real-time data analysis capabilities significantly improve throughput and quality control efficiency in high-volume manufacturing environments.

- Sustainability and Environmental Considerations: Utilizing energy-efficient LED lighting, minimizing waste in production processes, and offering eco-friendly packaging cater to customers with growing sustainability concerns.

Factors for Market Share Analysis:

- Product Portfolio and Technological Breadth: The range and sophistication of microscopes offered, encompassing different types like stereomicroscopes, compound microscopes, and digital microscopes, with varying magnification levels, imaging capabilities, and software integration, significantly impact market reach. Providing customized solutions for specific applications, such as high-resolution imaging for semiconductor inspection or 3D reconstruction for materials analysis, can be significant differentiators.

- Target Market Focus: Catering to specific segments within the industrial ecosystem, such as manufacturing, quality control, research and development, or forensics, requires tailored features and marketing strategies. Addressing the unique needs of each segment can solidify market share within that niche.

- Ease of Use and Ergonomics: Providing intuitive interfaces, user-friendly software, and ergonomically designed instruments are crucial for enhancing user experience, particularly for non-specialist technicians.

- Software and Data Management: Robust image capture and analysis software, data storage solutions, and seamless integration with laboratory information management systems (LIMS) offer workflow efficiency and facilitate data-driven decision-making.

- Pricing Strategy and Service Packages: Striking the right balance between affordability and feature depth is essential. Offering flexible pricing models like tiered configurations, leasing options, or service bundles with maintenance and training can broaden appeal and increase market penetration.

New and Emerging Companies:

- Niche-Focused Startups: Companies like Keyence and Hirox specialize in developing high-resolution, portable microscopes for specific applications like on-site inspection in the field, offering ruggedness and ease of use for non-laboratory settings.

- Software-Centric Platforms: Companies like Motic and Vision Engineering focus on developing software platforms that enhance traditional microscopes with image analysis tools, 3D reconstruction capabilities, and cloud-based data management, expanding accessibility and functionality.

- Open-Source Hardware Advocates: Companies like OpenFlexure and Microfluidics International promote open-source microscope designs and readily available schematics, empowering researchers and DIY enthusiasts with customization options and fostering innovation within the community.

Latest Company Updates:

Sep. 22, 2023, Titan Tool Supply, a leading global provider of optical instrumentation and precision micro finishing tools, launched the Model FX-3, a high-quality industrial-grade widefield stereo microscope. Model FX-3 is designed to facilitate various manufacturing and quality assurance remote visual inspection tasks. The new industrial-grade widefield stereo microscope produces upright and optically correct images, offering exceptional measurement performance.

May 09, 2023, Titan Tool Supply Inc. introduced its industrial inspection monocular zoom microscope, Model ZMM-1. The new microscope is designed to provide smaller components and materials manufacturers with reliable, accurate, real-time quality control and remote visual inspection capabilities across a full production cycle. Titan is a global supplier of industrial-grade optical instrumentation and precision microfinishing tools.

June 01, 2022, Vision Engineering launched a compact digital microscope, VE Cam, for various applications. Vision Engineering's compact digital microscope is a complete standalone inspection microscope suitable for various industrial applications such as circuit board examination, printed circuit board debugging activities/ discovering imperfections, and tracing problems.

Available in two variants, VE Cam 50 (50 mm FOV) and VE Cam 80 (80 mm FOV), with differing fields of view (FOV), these devices offer the power, speed and efficiency of digital imaging in a compact package. Vision Engineering's VE Cam enables users to have a smaller footprint, which makes it ideal for many routine inspection tasks. Moreover, the VE Cam is standalone and does not require a PC, keyboard or mouse.