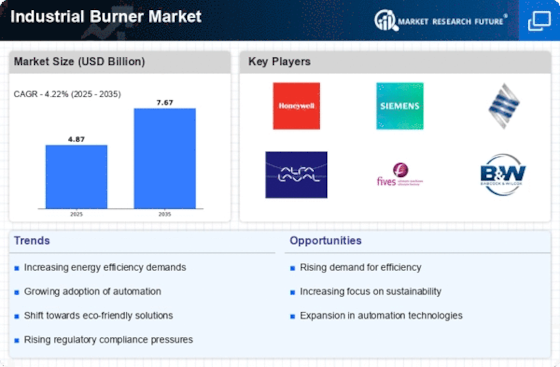

Rising Demand for Energy Efficiency

The Industrial Burner Market is experiencing a notable increase in demand for energy-efficient solutions. As industries strive to reduce operational costs and enhance productivity, the adoption of advanced burner technologies that optimize fuel consumption is becoming paramount. According to recent data, energy-efficient burners can reduce fuel usage by up to 30%, which translates into significant cost savings for manufacturers. This trend is further fueled by regulatory pressures aimed at minimizing carbon emissions, compelling companies to invest in more efficient systems. Consequently, the focus on energy efficiency is likely to drive innovation within the Industrial Burner Market, leading to the development of smarter, more adaptable burner systems that meet the evolving needs of various sectors.

Shift Towards Renewable Energy Sources

The shift towards renewable energy sources is emerging as a pivotal driver for the Industrial Burner Market. As industries seek to transition from fossil fuels to more sustainable energy options, the demand for burners that can efficiently utilize alternative fuels, such as biomass and biogas, is increasing. This transition is not only driven by environmental concerns but also by the potential for cost savings associated with renewable energy. Data suggests that the use of alternative fuels can reduce operational costs by up to 20% in certain applications. Consequently, the Industrial Burner Market is likely to witness a surge in innovation as manufacturers develop burners capable of accommodating a wider range of fuel types, aligning with the global push for sustainability.

Technological Innovations in Burner Design

Technological innovations are reshaping the Industrial Burner Market, with advancements in burner design and functionality leading the charge. The integration of smart technologies, such as IoT and automation, is enhancing the operational efficiency and monitoring capabilities of industrial burners. These innovations allow for real-time data analysis and predictive maintenance, which can significantly reduce downtime and operational costs. Furthermore, the introduction of low-NOx burners is addressing environmental concerns by minimizing harmful emissions. As industries increasingly prioritize sustainability, the demand for technologically advanced burners is expected to rise, indicating a transformative phase for the Industrial Burner Market.

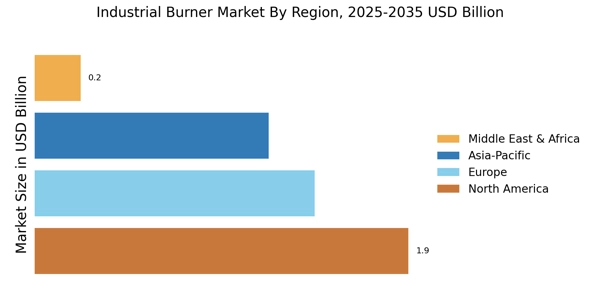

Growth in Manufacturing and Industrial Activities

The resurgence of manufacturing and industrial activities is a critical driver for the Industrial Burner Market. As economies recover and expand, there is a marked increase in production capacities across various sectors, including food processing, chemicals, and metals. This growth is accompanied by a rising need for reliable and efficient heating solutions, which industrial burners provide. Data indicates that the manufacturing sector is projected to grow at a compound annual growth rate of approximately 4% over the next few years, further propelling the demand for industrial burners. This trend suggests that as production scales up, the Industrial Burner Market will likely see a corresponding increase in demand for its products, thereby fostering further advancements in burner technology.

Regulatory Compliance and Environmental Standards

The Industrial Burner Market is significantly influenced by stringent regulatory compliance and environmental standards. Governments worldwide are implementing regulations aimed at reducing emissions and promoting cleaner technologies. This regulatory landscape compels industries to adopt burners that meet these standards, driving the demand for advanced burner solutions. For instance, the introduction of regulations limiting NOx emissions has led to a surge in the adoption of low-emission burners. As industries seek to comply with these regulations, the market for industrial burners is likely to expand, fostering innovation and the development of environmentally friendly technologies within the Industrial Burner Market.