Market Analysis

In-depth Analysis of Industrial Agitator Market Industry Landscape

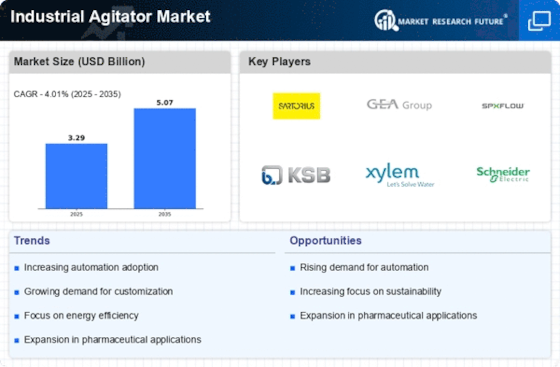

The Industrial Agitator market is subject to dynamic forces that shape its overall landscape and influence the behavior of key players within the industry. These market dynamics encompass a range of factors, playing a vital role in the growth, trends, and competitiveness of the Industrial Agitator market.

One of the primary dynamics is technological advancements. The continuous evolution of technologies in the industrial sector directly impacts the design and functionality of agitators. Innovations in materials, control systems, and automation contribute to the development of more efficient and sophisticated agitators. Manufacturers must stay abreast of these technological advancements to remain competitive and meet the increasing demands of industries striving for enhanced productivity and process optimization.

Market demand is a significant driver of the Industrial Agitator market dynamics. The demand for agitators is closely tied to the performance of key end-use industries such as chemicals, pharmaceuticals, food and beverages, and others. Fluctuations in demand from these sectors can be influenced by economic conditions, consumer preferences, and regulatory changes. Understanding and responding to these demand dynamics is crucial for agitator manufacturers to adjust production levels, optimize inventory, and effectively meet the needs of their customers.

Regulatory factors also exert a profound influence on the Industrial Agitator market dynamics. Governments worldwide implement regulations to ensure environmental compliance, workplace safety, and product quality. Agitator manufacturers need to adapt their products to meet these standards, which can impact design, materials used, and production processes. Staying compliant with regulations is not only a legal requirement but also a strategic move to maintain market credibility and customer trust.

Global economic conditions significantly affect the Industrial Agitator market dynamics. Economic downturns may result in reduced industrial activities and capital investments, affecting the demand for agitators. Conversely, periods of economic growth can lead to increased industrial production, driving the need for efficient mixing solutions. The cyclical nature of the global economy requires agitator manufacturers to be adaptable and responsive to changes in market conditions.

Competitive dynamics play a pivotal role in shaping the Industrial Agitator market landscape. The presence of multiple manufacturers vying for market share fosters competition, driving innovation and efficiency. Companies strategically position themselves through product differentiation, cost leadership, and market segmentation to gain a competitive edge. Collaborations, mergers, and acquisitions are common strategies employed by players seeking to strengthen their market position and expand their product portfolios.

Supply chain dynamics also contribute to the overall market dynamics of the Industrial Agitator market. Availability and cost of raw materials, logistical challenges, and disruptions in the supply chain can impact the production and delivery of agitators. Manufacturers need to establish resilient supply chains, diversify sourcing strategies, and implement risk mitigation measures to navigate uncertainties and ensure a steady supply of products to meet market demands.

Environmental and sustainability considerations are increasingly becoming integral to the market dynamics of the Industrial Agitator market. As industries focus on reducing their environmental footprint, there is a growing demand for agitators that are energy-efficient, use eco-friendly materials, and comply with sustainable manufacturing practices. Manufacturers incorporating green technologies and sustainable practices into their offerings gain a competitive advantage in a market where environmental consciousness is on the rise.

Leave a Comment