Sustainability Initiatives in Agitator Bead Mill Market

Sustainability initiatives are increasingly influencing the Agitator Bead Mill Market, as manufacturers seek to minimize their environmental impact. The demand for eco-friendly materials and processes is rising, prompting companies to adopt sustainable practices in their operations. This includes the use of recyclable bead materials and energy-efficient milling technologies. According to recent data, the market for sustainable milling solutions is projected to grow at a compound annual growth rate of over 5% in the coming years. By aligning with sustainability goals, companies in the Agitator Bead Mill Market can enhance their brand reputation and appeal to environmentally conscious consumers.

Technological Advancements in Agitator Bead Mill Market

The Agitator Bead Mill Market is experiencing a surge in technological advancements that enhance milling efficiency and product quality. Innovations such as improved bead materials and advanced milling techniques are being developed, which allow for finer particle sizes and better dispersion. For instance, the introduction of high-energy bead mills has been shown to reduce processing times significantly, thereby increasing productivity. Furthermore, automation and digitalization in milling processes are becoming prevalent, enabling manufacturers to optimize operations and reduce costs. As a result, these technological improvements are likely to attract more investments into the Agitator Bead Mill Market, fostering growth and competitiveness.

Growing Demand in Emerging Markets for Agitator Bead Mills

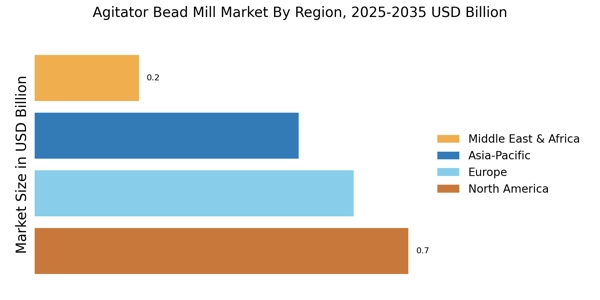

The Agitator Bead Mill Market is witnessing a growing demand in emerging markets, driven by rapid industrialization and urbanization. Countries in Asia-Pacific and Latin America are experiencing increased investments in manufacturing sectors, particularly in chemicals, coatings, and pharmaceuticals. This trend is expected to propel the demand for high-performance milling equipment, including agitator bead mills. Market analysis indicates that the Asia-Pacific region alone is anticipated to account for a significant share of the market by 2026, as local manufacturers seek advanced milling solutions to enhance product quality and production efficiency. This burgeoning demand presents lucrative opportunities for stakeholders in the Agitator Bead Mill Market.

Rising Applications Across Various Industries in Agitator Bead Mill Market

The versatility of agitator bead mills is contributing to their rising applications across various industries, thereby driving the Agitator Bead Mill Market. These mills are utilized in sectors such as paints and coatings, inks, pharmaceuticals, and food processing, where fine particle size and uniform dispersion are critical. The increasing need for high-quality products in these industries is likely to boost the demand for advanced milling technologies. For example, the pharmaceutical sector is particularly focused on achieving precise particle sizes for drug formulations, which is expected to enhance the adoption of agitator bead mills. This trend indicates a promising outlook for the Agitator Bead Mill Market.

Increased Investment in Research and Development in Agitator Bead Mill Market

Investment in research and development is a key driver for the Agitator Bead Mill Market, as companies strive to innovate and improve their product offerings. Enhanced R&D efforts are leading to the development of new milling technologies that cater to specific industry needs, such as higher efficiency and lower energy consumption. Recent reports suggest that companies are allocating a larger portion of their budgets to R&D, with some firms reporting increases of up to 15% in R&D spending. This focus on innovation is likely to result in the introduction of next-generation agitator bead mills, which could redefine performance standards in the market. Consequently, this trend is expected to foster growth and competitiveness within the Agitator Bead Mill Market.