Stringent Regulatory Compliance

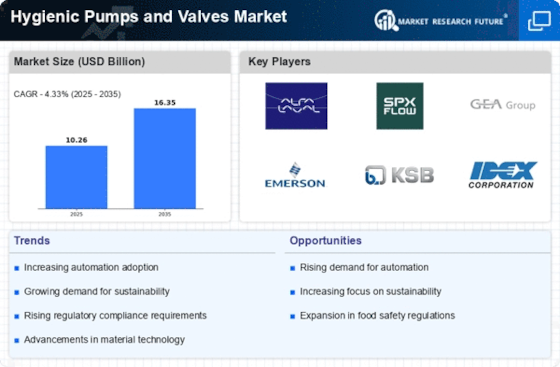

The Hygienic Pumps and Valves Market is significantly influenced by stringent regulatory compliance requirements imposed by health and safety authorities. These regulations are designed to ensure the safety and quality of products, particularly in sectors such as food processing and pharmaceuticals. Compliance with standards such as the FDA and EHEDG necessitates the use of hygienic pumps and valves that meet specific design and material criteria. As a result, manufacturers are increasingly investing in advanced technologies and materials to ensure their products adhere to these regulations. The market for hygienic pumps and valves is projected to expand as companies prioritize compliance, with an estimated growth rate of around 7% annually in the coming years.

Rising Demand for Process Automation

The Hygienic Pumps and Valves Market is experiencing a notable surge in demand for process automation across various sectors, particularly in food and beverage, pharmaceuticals, and biotechnology. This trend is driven by the need for enhanced efficiency, reduced labor costs, and improved product quality. Automation technologies, such as sensors and control systems, are increasingly integrated into hygienic pumps and valves, facilitating real-time monitoring and control of processes. According to recent data, the automation market is projected to grow at a compound annual growth rate of approximately 9% over the next five years. This growth is likely to propel the Hygienic Pumps and Valves Market, as manufacturers seek to optimize production processes while ensuring compliance with stringent hygiene standards.

Expansion of the Food and Beverage Sector

The Hygienic Pumps and Valves Market is closely linked to the expansion of the food and beverage sector, which is experiencing robust growth due to increasing consumer demand for processed and packaged foods. This expansion necessitates the use of hygienic pumps and valves to ensure the safe and efficient processing of food products. Market analysis suggests that the food and beverage industry is projected to grow at a rate of approximately 5% annually, driving the demand for hygienic processing equipment. As manufacturers strive to enhance production capabilities while adhering to hygiene standards, the Hygienic Pumps and Valves Market is likely to see substantial growth in the coming years, reflecting the interconnectedness of these sectors.

Growing Health Consciousness Among Consumers

The Hygienic Pumps and Valves Market is witnessing a shift in consumer behavior, characterized by a growing health consciousness. As consumers become more aware of the importance of hygiene and safety in food and beverage products, manufacturers are compelled to adopt higher standards of cleanliness in their production processes. This trend is particularly evident in the food and beverage sector, where the demand for hygienic processing equipment is on the rise. Market data indicates that the demand for hygienic pumps and valves is expected to increase by approximately 8% annually, driven by the need for safer and cleaner products. Consequently, manufacturers are investing in innovative solutions to meet these evolving consumer expectations.

Technological Advancements in Material Science

The Hygienic Pumps and Valves Market is benefiting from technological advancements in material science, which are enhancing the performance and durability of hygienic equipment. Innovations in materials such as stainless steel, polymers, and elastomers are enabling the production of pumps and valves that are not only more resistant to corrosion and wear but also easier to clean and maintain. These advancements are crucial for industries where hygiene is paramount, such as food processing and pharmaceuticals. The market is projected to grow as manufacturers leverage these new materials to improve product offerings, with an anticipated growth rate of around 6% over the next few years. This trend underscores the importance of material innovation in the Hygienic Pumps and Valves Market.