Market Analysis

In-depth Analysis of Hydraulic Equipment Market Industry Landscape

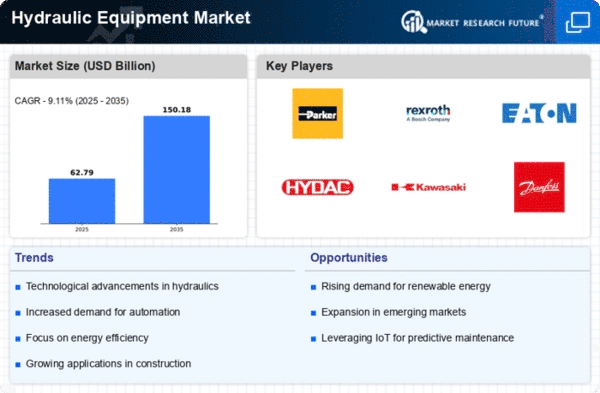

The Hydraulic Equipment Market functions within a dynamic landscape, influenced by a range of factors that shape its growth and trends. Hydraulic equipment, encompassing components such as pumps, cylinders, valves, and hoses, plays a crucial role in various industries, including construction, agriculture, aerospace, and manufacturing. The market dynamics of the Hydraulic Equipment sector are intricately linked to technological advancements, industry-specific demands, economic factors, and global trends.

New technology changes are guiding the moves of the Hydraulic Equipment market. constant work is done to make hydraulic systems better, more dependable and longer-lasting. Changes in materials, design and control systems help make hydraulic equipment more competitive. People who make things for the hydraulic gear business are always looking to create new and modern ways that help different kinds of businesses.

The needs of different industries have a big effect on how the market for Hydraulic Equipment works. Different areas like building, farming and making things each need special parts for hydraulic systems. For example, the building industry needs strong and big hydraulic tools for lifting heavy things or moving dirt. On the other hand, the plane business might use accurate but lightweight hydraulics systems in airplanes instead. People in the market need to change their water-based solutions so they can handle different issues and chances offered by each type of industry.

Price and money aspects play a role in how Hydraulic Equipment is bought and sold. The size of industries using hydraulic equipment, changes in the cost of goods and overall money conditions affect how much people want to use these tools. In times of economic growth, more infrastructure and factory work can cause a greater need for hydraulic systems. On the other side, if the economy goes down it could lead to less spending on big projects. This can affect how much hydraulic gear is bought and sold in markets.

World changes in being green and caring for our environment also impact how the Hydraulic Equipment market works. As companies work to lessen their effect on nature, there is an increasing focus on making hydraulic machines that use little energy and are kind to the environment. Factories are putting money into making good hydraulic devices that meet tough rules about the environment. This is part of a larger change in different areas to follow practices friendly for our planet.

The way markets work is affected by competition and working together in the business of hydraulic equipment. Makers work with people who use things, connect systems together and others to make special hydraulic stuff. This meets the exact needs of certain job types. Offering complete water systems, good service after the sale and fast supply chains are important things for companies to do well in a tough market of Hydraulic Equipment.

Globalization further shapes the market dynamics of Hydraulic Equipment. Manufacturers must navigate international trade policies, collaborate with global partners, and adapt their solutions to meet diverse market conditions. Access to emerging markets, understanding regional preferences, and compliance with varying regulatory standards become critical factors for success in the global Hydraulic Equipment market.

Leave a Comment