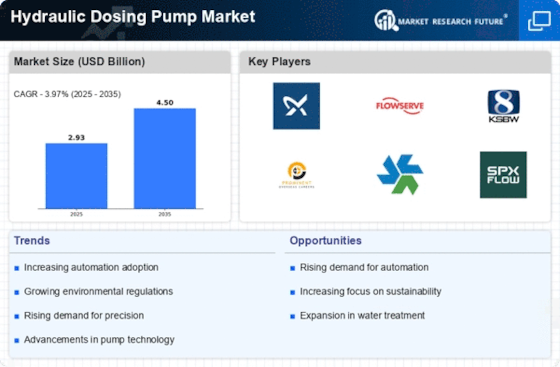

Increasing Demand in Water Treatment

The Hydraulic Dosing Pump Market is experiencing a notable surge in demand, particularly within the water treatment sector. As municipalities and industries strive to meet stringent water quality regulations, the need for precise chemical dosing has become paramount. This trend is underscored by the projected growth of the water treatment market, which is expected to reach USD 1 trillion by 2025. Hydraulic dosing pumps play a critical role in ensuring the accurate delivery of chemicals, thereby enhancing treatment efficiency. Furthermore, the rising awareness of water scarcity issues is likely to drive investments in advanced water treatment technologies, further propelling the hydraulic dosing pump market. The integration of automation and smart technologies in dosing systems is also anticipated to enhance operational efficiency, making hydraulic dosing pumps indispensable in modern water treatment facilities.

Technological Innovations and Automation

The Hydraulic Dosing Pump Market is witnessing a wave of technological innovations that are transforming dosing solutions. The integration of automation and smart technologies into hydraulic dosing pumps is enhancing their efficiency and reliability. Features such as real-time monitoring, remote control, and predictive maintenance are becoming increasingly common, allowing for improved operational performance. The market for automated dosing systems is expected to grow significantly, driven by the need for enhanced precision and reduced labor costs. Additionally, advancements in materials and design are leading to the development of more durable and efficient pumps, further boosting their appeal in various applications. As industries seek to optimize processes and reduce operational costs, the demand for technologically advanced hydraulic dosing pumps is likely to increase, positioning them as a vital component in modern industrial operations.

Industrial Growth and Chemical Processing

The Hydraulic Dosing Pump Market is significantly influenced by the expansion of the chemical processing sector. As industries such as pharmaceuticals, petrochemicals, and food processing continue to grow, the demand for reliable and efficient dosing solutions is expected to rise. The chemical processing industry alone is projected to reach USD 5 trillion by 2025, creating a substantial market for hydraulic dosing pumps. These pumps are essential for the accurate and consistent delivery of various chemicals, ensuring product quality and compliance with safety standards. Additionally, the increasing complexity of chemical formulations necessitates advanced dosing technologies, which hydraulic dosing pumps are well-equipped to provide. This trend indicates a robust future for the hydraulic dosing pump market, driven by the ongoing evolution of industrial processes and the need for precision in chemical handling.

Regulatory Compliance and Safety Standards

The Hydraulic Dosing Pump Market is significantly shaped by the stringent regulatory frameworks governing various sectors, particularly in pharmaceuticals and food and beverage. Compliance with safety and environmental regulations necessitates the use of precise dosing equipment to minimize risks associated with chemical handling. As regulations become more rigorous, industries are compelled to invest in advanced hydraulic dosing pumps that ensure accurate chemical dosing while adhering to safety standards. The market for hydraulic dosing pumps is projected to grow as companies prioritize compliance and risk management. Furthermore, the increasing focus on sustainability and environmental protection is likely to drive the adoption of hydraulic dosing pumps that minimize waste and enhance operational efficiency. This regulatory landscape presents both challenges and opportunities for manufacturers in the hydraulic dosing pump market, as they strive to meet evolving standards.

Rising Focus on Sustainability and Environmental Impact

The Hydraulic Dosing Pump Market is increasingly influenced by the global emphasis on sustainability and reducing environmental impact. Industries are under pressure to adopt practices that minimize waste and enhance resource efficiency. Hydraulic dosing pumps, known for their precision and efficiency, are becoming essential tools in achieving these sustainability goals. The market is likely to see a rise in demand for pumps that are designed to reduce chemical waste and energy consumption. Furthermore, as companies strive to meet corporate social responsibility objectives, the adoption of environmentally friendly dosing solutions is expected to grow. This trend is supported by the increasing availability of eco-friendly chemicals and the development of pumps that can handle these substances effectively. The focus on sustainability not only drives innovation in the hydraulic dosing pump market but also aligns with broader global efforts to promote environmental stewardship.