Growing Focus on Energy Efficiency

The High-voltage Composite Insulator Market is increasingly driven by the growing focus on energy efficiency within electrical systems. As energy costs rise and environmental concerns become more pressing, utilities are seeking ways to optimize their operations. High-voltage composite insulators contribute to energy efficiency by reducing transmission losses and enhancing the overall performance of power systems. It is estimated that the implementation of energy-efficient technologies could reduce operational costs by up to 20% for utilities. This trend is likely to encourage the adoption of high-voltage composite insulators, as they offer superior performance compared to traditional materials. Therefore, the emphasis on energy efficiency is a significant factor influencing the growth of the High-voltage Composite Insulator Market.

Government Regulations and Standards

The High-voltage Composite Insulator Market is significantly influenced by government regulations and standards aimed at enhancing electrical safety and reliability. Regulatory bodies are increasingly mandating the use of high-performance insulators to minimize outages and improve grid stability. These regulations often require utilities to upgrade their infrastructure, which in turn drives the demand for high-voltage composite insulators. As of 2025, it is estimated that compliance with these regulations will account for a substantial portion of the market growth, as utilities invest in modernizing their systems. Furthermore, the push for stricter environmental standards is likely to favor the adoption of composite materials, which are lighter and more resistant to environmental degradation. Therefore, government initiatives play a crucial role in shaping the landscape of the High-voltage Composite Insulator Market.

Technological Innovations in Insulator Design

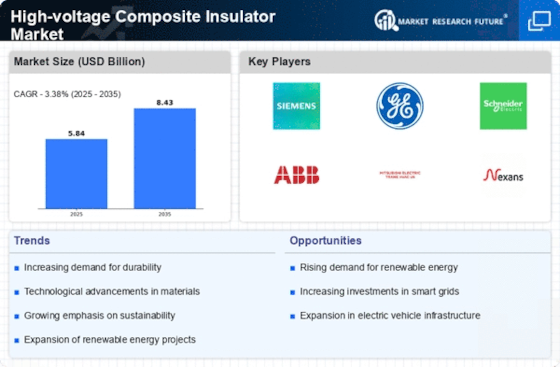

The High-voltage Composite Insulator Market is experiencing a surge in technological innovations that enhance the performance and durability of insulators. Advanced materials, such as silicone rubber and polymer composites, are being utilized to improve resistance to environmental factors, thereby extending the lifespan of insulators. This trend is supported by the increasing demand for reliable and efficient power transmission systems. As of 2025, the market for high-voltage composite insulators is projected to grow at a compound annual growth rate of approximately 6.5%, driven by these innovations. Manufacturers are investing in research and development to create insulators that can withstand extreme weather conditions, which is crucial for maintaining the integrity of power networks. Consequently, the focus on technological advancements is likely to propel the growth of the High-voltage Composite Insulator Market.

Rising Investment in Renewable Energy Projects

The High-voltage Composite Insulator Market is poised for growth due to the rising investment in renewable energy projects. As countries strive to meet sustainability goals, there is a notable increase in the installation of wind and solar power plants, which require efficient transmission systems. High-voltage composite insulators are essential for these applications, as they provide the necessary reliability and performance in challenging environments. Recent data indicates that investments in renewable energy infrastructure are expected to reach over USD 1 trillion by 2025, further driving the demand for high-voltage composite insulators. This trend suggests that the market will benefit from the integration of renewable energy sources into existing grids, necessitating the use of advanced insulator technologies. Thus, the focus on renewable energy is a significant driver for the High-voltage Composite Insulator Market.

Increasing Urbanization and Infrastructure Development

The High-voltage Composite Insulator Market is benefiting from the increasing urbanization and infrastructure development across various regions. As urban areas expand, the demand for reliable electricity supply becomes paramount, necessitating the installation of advanced power transmission systems. High-voltage composite insulators are particularly suited for urban environments due to their lightweight and high-performance characteristics. Recent projections indicate that urbanization rates are expected to rise, with over 60% of the population living in urban areas by 2030. This demographic shift is likely to drive investments in electrical infrastructure, thereby boosting the demand for high-voltage composite insulators. Consequently, the interplay between urbanization and infrastructure development is a key driver for the High-voltage Composite Insulator Market.