Increased Focus on Patient Safety

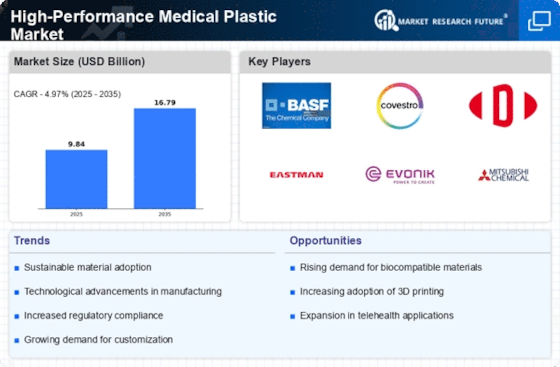

The High-Performance Medical Plastic Market is increasingly shaped by a heightened focus on patient safety and product reliability. Regulatory bodies are enforcing stricter guidelines regarding the materials used in medical devices, emphasizing the need for biocompatibility and non-toxicity. This regulatory landscape compels manufacturers to adopt high-performance plastics that meet these safety standards. As a result, the market for high-performance medical plastics is projected to grow, with an estimated increase of 5% annually as companies invest in compliant materials. This focus on safety not only protects patients but also enhances the reputation of manufacturers, fostering trust in their products.

Innovations in Polymer Technology

Innovations in polymer technology are significantly influencing the High-Performance Medical Plastic Market. The development of new polymer blends and composites enhances the mechanical properties and functionality of medical plastics. For instance, advancements in polyether ether ketone (PEEK) and polycarbonate materials have led to improved strength and thermal stability, which are essential for high-stress medical applications. The market for these advanced polymers is expected to witness a compound annual growth rate of around 8% through 2025. This innovation not only meets the stringent requirements of medical applications but also opens avenues for new product development, thereby driving the overall market growth.

Rising Demand for Medical Devices

The High-Performance Medical Plastic Market is experiencing a surge in demand for advanced medical devices. This trend is driven by an increasing prevalence of chronic diseases and an aging population, which necessitates innovative healthcare solutions. According to recent data, the medical device market is projected to reach approximately 600 billion USD by 2025, with high-performance plastics playing a crucial role in device manufacturing. These materials offer superior biocompatibility, durability, and sterilization capabilities, making them ideal for applications in surgical instruments, implants, and diagnostic equipment. As healthcare providers seek to enhance patient outcomes and operational efficiency, the reliance on high-performance medical plastics is likely to grow, further propelling market expansion.

Growth in Minimally Invasive Procedures

The High-Performance Medical Plastic Market is benefiting from the growth of minimally invasive surgical procedures. These techniques, which are preferred for their reduced recovery times and lower risk of complications, require specialized medical devices made from high-performance plastics. The market for minimally invasive devices is anticipated to reach 50 billion USD by 2025, with high-performance plastics being integral to their design and functionality. The lightweight and flexible nature of these materials allows for the creation of intricate devices that can navigate the human body with precision. As the demand for such procedures continues to rise, the reliance on high-performance medical plastics is expected to increase correspondingly.

Emerging Markets and Healthcare Investments

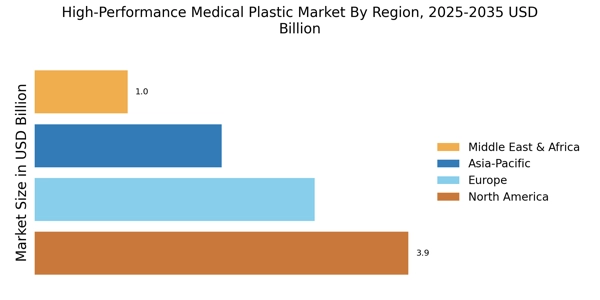

Emerging markets are becoming increasingly important in the High-Performance Medical Plastic Market. As countries invest in healthcare infrastructure and expand access to medical services, the demand for advanced medical devices is rising. For instance, regions in Asia and Latin America are witnessing significant growth in healthcare spending, projected to increase by 10% annually. This trend creates opportunities for high-performance medical plastics, which are essential for manufacturing a wide range of medical devices. As these markets develop, the need for innovative and reliable materials will likely drive the expansion of the high-performance medical plastic sector, presenting lucrative opportunities for manufacturers.