Advancements in Material Technology

Advancements in material technology are poised to drive innovation within the Heat Shrink Tubing Market. The development of new polymer blends and additives enhances the performance characteristics of heat shrink tubing, such as temperature resistance, flexibility, and chemical stability. These improvements are particularly relevant in industries that require high-performance materials, such as aerospace and medical devices. As manufacturers increasingly prioritize quality and durability, the market is likely to witness a shift towards premium heat shrink tubing solutions, which could lead to higher profit margins and increased competition among suppliers.

Growth in Telecommunications Sector

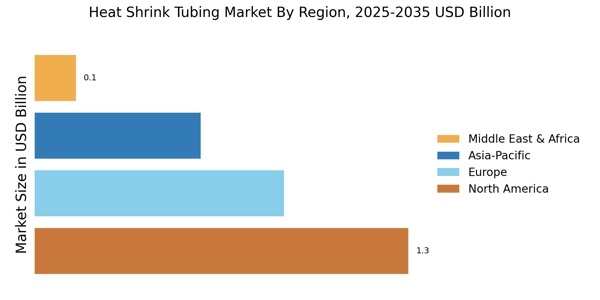

The telecommunications sector's expansion is likely to significantly influence the Heat Shrink Tubing Market. With the ongoing rollout of 5G networks and the increasing demand for high-speed data transmission, the need for effective cable management and protection solutions is paramount. Heat shrink tubing provides essential insulation and strain relief for fiber optic and coaxial cables, which are critical in telecommunications infrastructure. As investments in telecommunications infrastructure continue to rise, the market for heat shrink tubing is expected to experience robust growth, potentially reaching a valuation of several billion dollars by 2026.

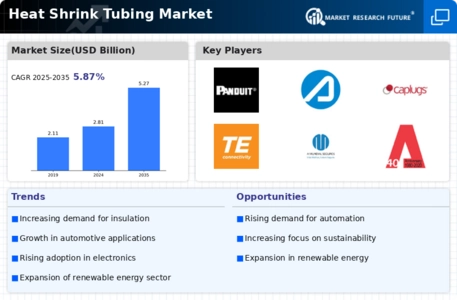

Rising Demand in Electrical Applications

The increasing demand for heat shrink tubing in electrical applications appears to be a primary driver for the Heat Shrink Tubing Market. As industries such as automotive, aerospace, and consumer electronics expand, the need for reliable insulation and protection of electrical components intensifies. In 2025, the electrical segment is projected to account for a substantial share of the market, driven by the growing adoption of electric vehicles and renewable energy systems. This trend suggests that manufacturers are likely to focus on developing heat shrink tubing that meets stringent safety and performance standards, thereby enhancing the overall market landscape.

Regulatory Compliance and Safety Standards

The stringent regulatory compliance and safety standards across various industries are likely to propel the Heat Shrink Tubing Market. As organizations strive to meet safety regulations, the demand for high-quality heat shrink tubing that adheres to international standards becomes critical. This is particularly evident in sectors such as automotive and aerospace, where failure to comply with safety standards can result in severe consequences. Consequently, manufacturers are expected to invest in research and development to produce heat shrink tubing that not only meets but exceeds regulatory requirements, thereby enhancing their market position.

Increased Focus on Renewable Energy Solutions

The heightened focus on renewable energy solutions is anticipated to be a significant driver for the Heat Shrink Tubing Market. As countries and corporations commit to reducing carbon footprints, the demand for efficient energy transmission and distribution systems grows. Heat shrink tubing plays a vital role in protecting electrical connections in solar panels and wind turbines, ensuring optimal performance and longevity. The renewable energy sector is projected to witness substantial investments, which may lead to an increased demand for heat shrink tubing, thereby contributing to the overall market growth in the coming years.