Growth in Renewable Energy Sector

The Heat-Resistant Polymer Market is likely to benefit from the expansion of the renewable energy sector, particularly in solar and wind energy applications. Heat-resistant polymers are increasingly utilized in components such as solar panels and wind turbine blades, where they must endure high temperatures and environmental stressors. The renewable energy market is projected to grow significantly, with estimates indicating a compound annual growth rate of around 8% in the coming years. This growth is driven by the global shift towards sustainable energy solutions, which necessitates the use of advanced materials that can withstand extreme conditions, thereby enhancing the demand for heat-resistant polymers.

Rising Demand in Aerospace Applications

The Heat-Resistant Polymer Market is experiencing a notable surge in demand due to the increasing utilization of heat-resistant polymers in aerospace applications. These materials are essential for components that must withstand extreme temperatures and harsh environments. The aerospace sector is projected to grow significantly, with estimates suggesting a compound annual growth rate of around 4.5% over the next few years. This growth is driven by the need for lightweight, durable materials that can enhance fuel efficiency and performance. As manufacturers seek to improve aircraft design and functionality, the adoption of heat-resistant polymers is likely to expand, thereby bolstering the market.

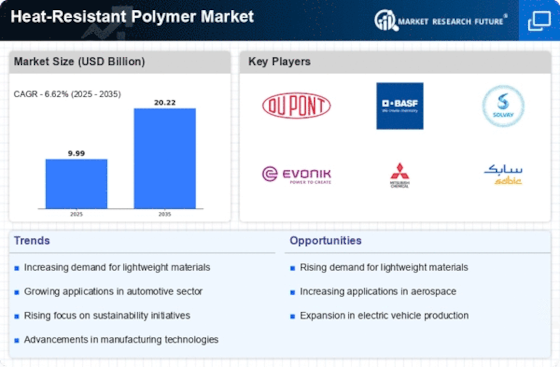

Advancements in Manufacturing Technologies

The Heat-Resistant Polymer Market is benefiting from advancements in manufacturing technologies, which are enabling the production of high-performance polymers with enhanced properties. Innovations such as 3D printing and advanced molding techniques are allowing for the creation of complex geometries and tailored material properties. The market for heat-resistant polymers is projected to grow at a compound annual growth rate of around 6% as these technologies become more widely adopted. As industries seek to optimize production processes and reduce costs, the ability to produce customized heat-resistant polymers will likely enhance their application across various sectors, thereby driving market growth.

Increased Focus on Automotive Lightweighting

The Heat-Resistant Polymer Market is experiencing growth due to the automotive sector's increasing focus on lightweighting to improve fuel efficiency and reduce emissions. Heat-resistant polymers are being integrated into various automotive components, including engine parts and exhaust systems, where they can withstand high temperatures. The automotive industry is expected to grow at a rate of approximately 3% annually, driven by stringent regulations on emissions and the push for more sustainable vehicles. As manufacturers seek to enhance vehicle performance while adhering to environmental standards, the adoption of heat-resistant polymers is likely to rise, further driving market expansion.

Expansion in Electronics and Electrical Industries

The Heat-Resistant Polymer Market is poised for growth as the electronics and electrical sectors increasingly adopt heat-resistant polymers for various applications. These materials are crucial for components such as circuit boards, connectors, and insulators, which require high thermal stability. The electronics industry is anticipated to grow at a rate of approximately 5% annually, driven by advancements in technology and the demand for miniaturized devices. As electronic devices become more compact and powerful, the need for materials that can withstand elevated temperatures without compromising performance is becoming more pronounced, thus propelling the heat-resistant polymer market.