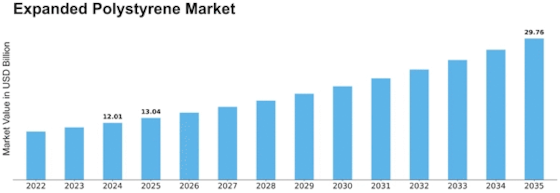

Expanded Polystyrene Size

Expanded Polystyrene Market Growth Projections and Opportunities

The expanded polystyrene (EPS) market is influenced by several market factors that shape its growth and demand dynamics. These factors include raw material availability, end-user industries, technological advancements, environmental regulations, and regional economic conditions.

Expanded Polystyrene formed by the polymerization process. This is a thermoplastic product composed of styrene beads. It is lightweight, has high durability and is resistant to moisture, extremely versatile. They are used for construction, building, automotive, and packaging.

Raw material availability plays a significant role in the EPS market. Polystyrene, the primary raw material used in EPS production, is derived from petroleum. Fluctuations in crude oil prices can directly impact the cost of production for EPS manufacturers. Additionally, the availability of styrene monomer, a key component of polystyrene, can affect EPS production capacity and pricing.

The demand for EPS is closely tied to various end-user industries, such as packaging, construction, and automotive. The packaging industry accounts for a significant portion of EPS consumption due to its lightweight, insulating properties, and shock-absorbing capabilities, making it ideal for protecting fragile goods during transit. In the construction sector, EPS is widely used in insulation applications for its thermal efficiency and cost-effectiveness. Similarly, the automotive industry utilizes EPS in components such as automotive interiors, under-the-hood applications, and lightweight structural parts.

Technological advancements drive innovation and efficiency in EPS manufacturing processes. Continuous efforts to develop sustainable and energy-efficient production methods contribute to reducing the environmental footprint of EPS manufacturing. Additionally, advancements in EPS processing technologies enhance product quality, customization capabilities, and cost-effectiveness, thereby expanding its applications across various industries.

Environmental regulations play a crucial role in shaping the EPS market landscape. Increased awareness of environmental issues, such as plastic pollution and carbon emissions, has led to the implementation of stricter regulations governing the use and disposal of EPS products. As a result, EPS manufacturers are increasingly adopting sustainable practices, such as recycling and incorporating bio-based or recyclable materials into their product offerings, to meet regulatory requirements and consumer demands for eco-friendly alternatives.

Regional economic conditions also influence the demand for EPS products. Economic growth, infrastructure development, and construction activities drive the demand for EPS insulation materials in emerging markets. Additionally, factors such as population growth, urbanization, and disposable income levels impact the consumption of packaged goods, further driving the demand for EPS packaging solutions.

Leave a Comment