Top Industry Leaders in the Engineering Plastic Market

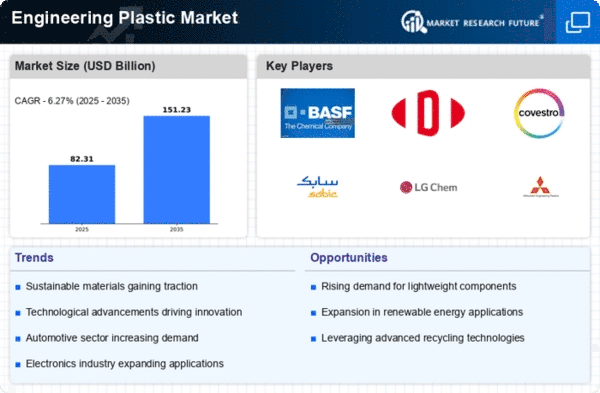

Engineering Plastic Market

The engineering plastics market is a dynamic and ever-evolving arena where innovation and strategic prowess reign supreme. This high-performance material, prized for its exceptional strength, durability, and resistance to heat and chemicals, finds its way into diverse applications across industries like automotive, aerospace, electronics, and medical. But amidst this growth, a fierce battle for market share unfolds, with established players and nimble newcomers vying for dominance.

Strategies Adopted: A Recipe for Success

Leading companies in the engineering plastics market employ a blend of strategies to stay ahead of the curve:

-

Product Diversification: Offering a wide range of engineering plastics with varying properties caters to specific end-use needs, attracting a broader customer base. -

Technological Innovation: Continuous investment in R&D leads to the development of new grades and formulations with enhanced performance characteristics, opening up new market segments. -

Vertical Integration: Gaining control over raw materials and production processes improves cost-efficiency and product quality, strengthening competitiveness. -

Strategic Partnerships: Collaborations with end-use manufacturers and research institutions accelerate innovation and market access. -

Sustainability Focus: Developing eco-friendly engineering plastics with improved recyclability and biodegradability addresses environmental concerns and attracts socially conscious consumers.

Factors Dictating Market Share: The Winning Formula

Several factors play a crucial role in determining market share in the engineering plastics arena:

-

Product Portfolio Breadth: A diverse range of offerings catering to different applications attracts a wider customer base. -

Brand Reputation: A well-established brand with a proven track record of quality and reliability inspires trust and loyalty. -

Geographical Presence: Strong presence in key markets, especially Asia-Pacific, provides access to a larger consumer base and favorable economic conditions. -

Cost Competitiveness: Efficient production processes and economies of scale enable companies to offer competitive prices, especially crucial in price-sensitive segments. -

Customer Service Excellence: Responsive and efficient customer service builds trust and fosters long-term relationships.

Key Companies in the engineering plastic market include

- du Pont de Nemours and Company (U.S.)

- Evonik Industries AG (Germany)

- Mitsubishi Engineering-Plastics Corporation (Japan)

- LG Chem Ltd. (South Korea)

- Lanxess AG (Germany)

- Celanese Corporation (US)

- Saudi Basic Industries Corporation (Saudi Arabia)

Recent Developments:

-

July: Evonik Industries acquires a bioplastics company, solidifying its commitment to sustainable engineering plastics. -

August: BASF expands its production capacity for high-performance polyamides in Asia to meet growing demand. -

September: Mitsubishi Chemical Corporation develops a new flame-retardant polycarbonate for improved safety in electronic devices. -

October: ExxonMobil announces plans to invest in a new engineering plastics manufacturing facility in the US. -

November: The European Commission proposes new regulations on the use of certain engineering plastics in food packaging to address concerns about microplastics. -

December: A consortium of leading engineering plastics manufacturers launches a joint initiative to develop standardized recycling protocols for the industry.