Growth in End-Use Industries

The Global Plastic Coatings Market Industry benefits from robust growth in end-use industries such as automotive, construction, and consumer goods. The automotive sector, in particular, is experiencing a surge in demand for lightweight and corrosion-resistant coatings, which enhance vehicle performance and aesthetics. Similarly, the construction industry is increasingly utilizing plastic coatings for protective and decorative purposes in residential and commercial buildings. This expansion in end-use industries is expected to propel the market forward, with projections indicating a market size of 7.3 USD Billion by 2024. The diverse applications of plastic coatings across these sectors underline their versatility and importance.

Rising Demand for Durable Coatings

The Global Plastic Coatings Market Industry experiences a notable increase in demand for durable coatings across various sectors. Industries such as automotive, construction, and electronics are increasingly adopting plastic coatings due to their superior resistance to wear, corrosion, and chemicals. This trend is driven by the need for long-lasting products that can withstand harsh environments. As a result, the market is projected to reach 7.3 USD Billion in 2024, reflecting a growing preference for high-performance coatings. The durability offered by these coatings not only enhances product lifespan but also reduces maintenance costs, making them an attractive option for manufacturers.

Emerging Markets and Global Expansion

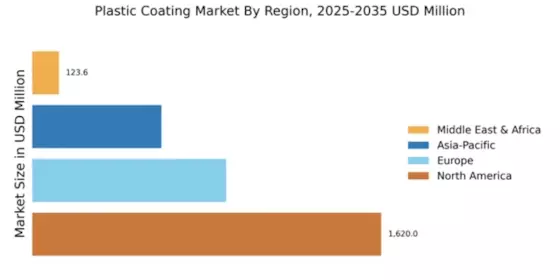

Emerging markets are becoming increasingly significant in the Global Plastic Coatings Market Industry. Countries in Asia-Pacific, Latin America, and Africa are witnessing rapid industrialization and urbanization, leading to heightened demand for plastic coatings in various applications. The growth of the middle class in these regions is also driving consumer spending on durable goods, further boosting the market. As manufacturers seek to expand their global footprint, they are likely to invest in these emerging markets, capitalizing on the growth opportunities they present. This trend is expected to contribute to the overall market growth, with a projected CAGR of 5.33% from 2025 to 2035.

Technological Advancements in Coating Processes

Technological advancements play a pivotal role in shaping the Global Plastic Coatings Market Industry. Innovations in coating processes, such as electrostatic spraying and powder coating, enhance the efficiency and effectiveness of plastic coatings. These technologies enable better adhesion, uniform application, and reduced waste, which are crucial for meeting the stringent quality standards of various industries. Furthermore, the integration of automation and robotics in coating applications is likely to streamline production processes, thereby increasing output. As these technologies evolve, they are expected to contribute to the market's growth, potentially reaching 12.9 USD Billion by 2035.

Environmental Regulations and Sustainability Initiatives

The Global Plastic Coatings Market Industry is significantly influenced by increasing environmental regulations and sustainability initiatives. Governments worldwide are implementing stricter regulations to minimize the environmental impact of industrial processes, prompting manufacturers to adopt eco-friendly coatings. Water-based and solvent-free plastic coatings are gaining traction as they align with sustainability goals. This shift not only helps companies comply with regulations but also appeals to environmentally conscious consumers. As a result, the market is likely to witness a compound annual growth rate of 5.33% from 2025 to 2035, driven by the demand for sustainable coating solutions.