Growing Focus on Quality Control

The Cylindrical Grinder Market is witnessing a growing focus on quality control measures within manufacturing processes. As industries become more competitive, the need for high-quality products has intensified, prompting manufacturers to invest in advanced grinding technologies. Cylindrical grinders play a crucial role in ensuring that components meet stringent quality standards, particularly in sectors such as aerospace and medical devices. Recent data indicates that the quality control market is projected to expand at a rate of 5% annually, which is likely to correlate with increased investments in cylindrical grinding equipment. This emphasis on quality not only enhances product reliability but also fosters customer satisfaction, thereby driving demand for cylindrical grinders in various manufacturing applications.

Expansion of Manufacturing Facilities

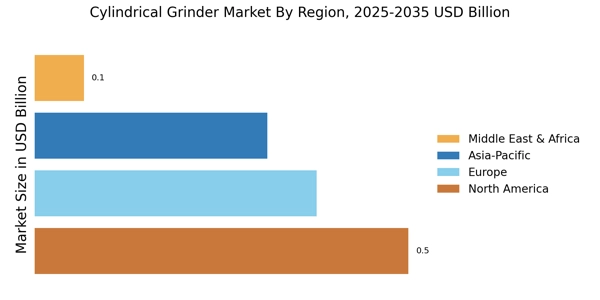

The Cylindrical Grinder Market is poised for growth due to the expansion of manufacturing facilities in emerging economies. Countries are increasingly investing in infrastructure and industrial development, leading to a surge in manufacturing activities. This trend is particularly evident in regions where labor costs are competitive, and there is a growing focus on local production. As new manufacturing plants are established, the demand for cylindrical grinders is likely to rise, as these machines are integral to the production process. Recent statistics indicate that manufacturing output in several developing regions is expected to increase by over 5% annually, creating a favorable environment for the cylindrical grinder market. The establishment of new facilities not only boosts demand for grinding machines but also encourages technological advancements in the industry.

Increased Automation in Manufacturing

The Cylindrical Grinder Market is significantly influenced by the trend towards increased automation in manufacturing processes. As companies seek to enhance productivity and reduce operational costs, the integration of automated grinding solutions is becoming more prevalent. Automation allows for higher throughput, reduced labor costs, and improved consistency in product quality. Recent market analyses suggest that the automation segment within the manufacturing industry is expected to grow at a rate of 7% annually, which could lead to a corresponding rise in demand for cylindrical grinders equipped with advanced automation features. This shift towards automated solutions not only enhances efficiency but also positions manufacturers to meet the evolving demands of the market, thereby driving growth in the cylindrical grinder sector.

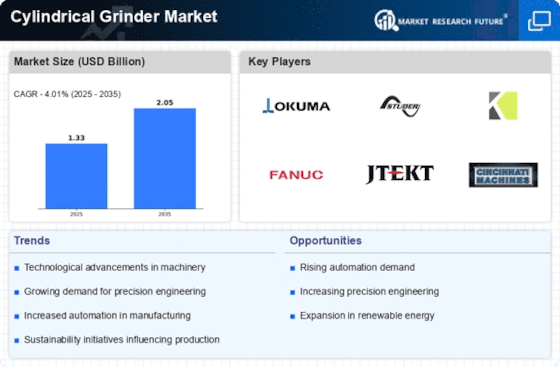

Rising Demand for Precision Engineering

The Cylindrical Grinder Market is experiencing a notable increase in demand for precision engineering components across various sectors, including automotive, aerospace, and manufacturing. As industries strive for higher accuracy and efficiency, the need for advanced grinding solutions becomes paramount. According to recent data, the precision engineering sector is projected to grow at a compound annual growth rate of approximately 6% over the next five years. This growth is likely to drive investments in cylindrical grinding technologies, as manufacturers seek to enhance their production capabilities. The emphasis on quality and precision in component manufacturing is expected to further propel the cylindrical grinder market, as these machines are essential for achieving the required tolerances and surface finishes in high-performance applications.

Emergence of Advanced Grinding Technologies

The Cylindrical Grinder Market is being shaped by the emergence of advanced grinding technologies, which are revolutionizing traditional grinding processes. Innovations such as computer numerical control (CNC) and hybrid grinding systems are enhancing the capabilities of cylindrical grinders, allowing for greater precision and efficiency. These advancements are particularly relevant in high-tech industries where the demand for complex geometries and tight tolerances is increasing. Market forecasts suggest that the adoption of advanced grinding technologies could lead to a growth rate of 8% in the cylindrical grinder market over the next few years. As manufacturers seek to remain competitive, the integration of these technologies into their production processes is likely to drive further investments in cylindrical grinding solutions.