Growing Emphasis on Customization

The growing emphasis on customization in product design is a notable driver in the Conventional And Rapid Prototyping Market. As consumer preferences shift towards personalized products, manufacturers are increasingly utilizing rapid prototyping techniques to meet these demands. This trend is particularly evident in sectors such as fashion, healthcare, and consumer goods, where tailored solutions are becoming the norm. In 2025, the market for customized prototyping solutions is expected to expand by 20%, as companies seek to differentiate their offerings. Rapid prototyping allows for quick adjustments and iterations based on consumer feedback, facilitating a more responsive design process. This adaptability not only enhances customer satisfaction but also fosters brand loyalty, thereby contributing to the overall growth of the Conventional And Rapid Prototyping Market.

Integration of Advanced Technologies

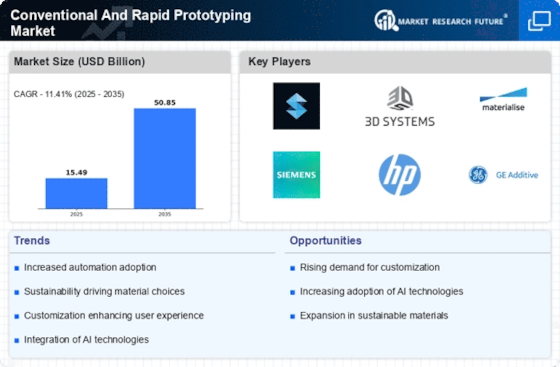

The integration of advanced technologies such as 3D printing, computer-aided design (CAD), and artificial intelligence is transforming the Conventional And Rapid Prototyping Market. These technologies enable designers and engineers to create highly complex prototypes with greater precision and efficiency. For instance, the adoption of 3D printing has revolutionized the prototyping process, allowing for the production of intricate designs that were previously unattainable. In 2025, it is estimated that the market for 3D printing in prototyping will reach USD 10 billion, reflecting a growing trend towards digital manufacturing. This technological evolution not only enhances the quality of prototypes but also reduces material waste, aligning with sustainability goals. Consequently, the incorporation of these advanced technologies is likely to drive significant growth in the Conventional And Rapid Prototyping Market.

Cost Efficiency and Resource Optimization

Cost efficiency and resource optimization are critical factors driving the Conventional And Rapid Prototyping Market. As businesses strive to minimize production costs while maximizing output, the adoption of rapid prototyping technologies becomes increasingly attractive. These methods allow for the rapid creation of prototypes, significantly reducing the time and resources required for traditional manufacturing processes. In 2025, it is projected that companies utilizing rapid prototyping will experience a 30% reduction in development costs, enabling them to allocate resources more effectively. This financial advantage is particularly appealing to small and medium-sized enterprises, which may lack the capital for extensive R&D. By streamlining the prototyping process, businesses can enhance their operational efficiency, thereby fostering growth within the Conventional And Rapid Prototyping Market.

Increased Demand for Prototyping Solutions

The rising demand for prototyping solutions is a key driver in the Conventional And Rapid Prototyping Market. Industries such as automotive, aerospace, and consumer electronics are increasingly adopting prototyping technologies to accelerate product development cycles. In 2025, the market is projected to witness a growth rate of approximately 15%, driven by the need for faster time-to-market and reduced development costs. Companies are leveraging both conventional and rapid prototyping methods to enhance innovation and streamline production processes. This trend indicates a shift towards more agile manufacturing practices, where rapid iterations and testing are essential for meeting consumer expectations. As businesses strive to remain competitive, the integration of advanced prototyping solutions becomes imperative, thereby propelling the growth of the Conventional And Rapid Prototyping Market.

Rising Investment in Research and Development

Rising investment in research and development (R&D) is a pivotal driver in the Conventional And Rapid Prototyping Market. Companies across various sectors are increasingly allocating funds towards R&D initiatives to foster innovation and improve product offerings. In 2025, it is anticipated that global R&D spending will exceed USD 2 trillion, with a significant portion directed towards prototyping technologies. This investment is crucial for developing new materials and processes that enhance the capabilities of both conventional and rapid prototyping methods. As organizations seek to maintain a competitive edge, the focus on R&D is likely to accelerate advancements in prototyping technologies, thereby propelling growth in the Conventional And Rapid Prototyping Market.