Market Trends

Introduction

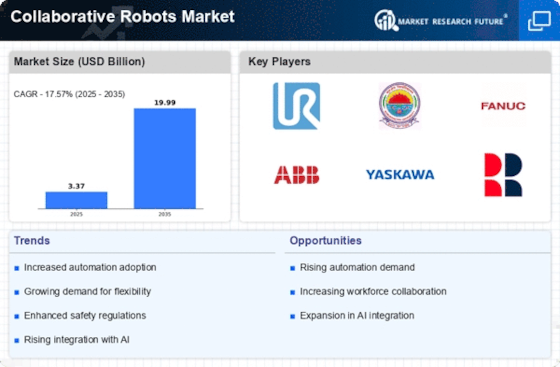

The Collaborative Robots Market is undergoing a major transformation as we enter 2024, owing to a combination of macroeconomic factors. Technology, especially artificial intelligence and machine learning, has greatly improved the capabilities and applications of these robots, which have become more available and efficient for a wider range of industries. Also, the regulatory framework, which aims to improve the safety of the workplace and the efficiency of the production process, is pushing companies to adopt automation solutions that meet the new standards. Also, the changing habits of consumers, characterized by a growing demand for customization and shorter production cycles, are forcing manufacturers to adopt these robots. These are strategic trends for the market, influencing not only the investment decisions but also the competitive dynamics.

Top Trends

-

Increased Adoption in Manufacturing

In recent years, manufacturers have increasingly begun to use cobots, or collaborative robots, to improve their productivity and efficiency. According to a survey conducted by the International Federation of Robotics,60% of manufacturers plan to use cobots by 2025. This trend is largely due to the need for flexible automation solutions that can be used alongside human workers, reducing labor costs and increasing output. ABB and KUKA are leading the way in this field. Cobots have the potential to reduce downtime and improve safety. -

Advancements in AI and Machine Learning

The cobots are a new revolution in the world of automation. Companies like Universal Robots are developing smarter cobots that can learn from their surroundings and adapt to new tasks. According to a study, the use of cobots with artificial intelligence can increase the efficiency of a company by up to 30 percent. This development not only increases productivity, but also opens up for more complex applications in the health and logistics industries and thus reshapes the relationship between man and machine. -

Regulatory Support and Standards Development

The governments are beginning to realize the importance of the cobots, and are establishing regulations to ensure their safe use in the factories. The ISO/TS 15066 standard is becoming increasingly important. This will increase the confidence of users and accelerate the take-up. As more industries adopt these standards, the landscape will change towards safer and more productive work. -

Focus on Human-Robot Collaboration

This new emphasis on human-robot collaboration is transforming the workplace. The cobots are designed to work with humans rather than to replace them. The results are clear: 70 per cent of workers believe that collaborating with robots makes them more productive. The trend is especially evident in the assembly and packaging industries, where companies such as Techman Robot are leading the way. The impact on business performance is high, with reduced staff turnover and increased staff satisfaction. The workplace is more harmonious. -

Customization and Flexibility in Design

Customized cobots are in great demand, enabling companies to develop their own bespoke solutions. In fact, companies like FANUC offer a range of cobots in a number of sizes that can be adapted to suit different tasks. A recent survey found that 55% of manufacturers prefer flexible automation solutions. This trend to more flexible automation solutions increases the productivity of a company and reduces the time it takes to reconfigure automation cells. -

Integration with IoT and Industry 4.0

A converging co-bot technology is the driving force of the Industry 4.0 revolution. Co-bots, with IoT-enabled sensors and controllers, can communicate with other machines and systems to create smarter manufacturing processes. The IoT-enabled co-bots are reported to reduce the costs of operations by up to 20%. Moreover, this trend is expected to enhance the data-driven decision-making and predictive maintenance, resulting in higher productivity and efficiency. -

Expansion into New Industries

In the meantime, the use of co-bots is spreading to the agricultural, health, and retail industries. For example, they are used in hospitals for the delivery of medicines. A survey has revealed that forty per cent of hospitals are already considering the introduction of co-bots. In addition to opening up new markets, this diversification also presents new operational challenges and opportunities for innovation in various industries. -

Sustainability and Energy Efficiency

A key feature of the development of new robots is their energy-saving design. The latest research shows that energy-efficient cobots can reduce running costs by up to 15 per cent. This trend is likely to continue, as pressure on all industries to adopt sustainable practices increases. The result will be a further improvement in the greening of manufacturing processes and a reduction in their impact on the environment. -

Enhanced Safety Features

In the development of cooperative robots, safety remains the prime concern, with progress being made in the field of sensors and safety systems. Co-workers and robots can be safely operated side by side. Statistics show that the accident rate falls by half in the presence of co-bots. This trend not only increases the safety of workers but also gives a higher degree of confidence in the co-bots in the various industries. -

Rise of Collaborative Robot Startups

The market for cooperative robots is seeing a surge of start-ups specializing in new cobot solutions. These agile, quick-moving companies can often respond quickly to market needs, which drives competition and innovation. A report has found that the number of start-ups has increased by a quarter in the past year. This trend is likely to result in a more varied offering and faster development of cobot technology, and this will have an impact on the established players in the market.

Conclusion: Navigating the Collaborative Robots Landscape

The market for the robots is very fragmented. As we approach 2024, the market is fragmented between the established companies and the newcomers. The trend of the regions is towards an increasing use of robots in North America and Europe, where the technological development of artificial intelligence and automation is the greatest, and where Asia-Pacific is catching up with its own solutions, which are adapted to local manufacturing conditions. The vendors will have to strategically position themselves with the help of artificial intelligence, automation, sustainability and flexibility in order to establish themselves as market leaders. The established players are focusing on improving their existing solutions, while the new companies are disrupting the market with agile, new solutions. It is therefore necessary for decision-makers to focus on strategic alliances and investments in these key areas in order to be able to master the changing market.

Leave a Comment