Top Industry Leaders in the Co Fired Ceramic Market

In the realm of materials science, where artistry meets engineering, lies a fascinating world: the co-fired ceramic market. These miniature marvels, meticulously crafted by the marriage of high temperatures and multiple materials, are revolutionizing diverse industries. Let's delve into the competitive landscape of this smoldering market, exploring the strategies, market share factors, industry news, and recent developments shaping its trajectory.

In the realm of materials science, where artistry meets engineering, lies a fascinating world: the co-fired ceramic market. These miniature marvels, meticulously crafted by the marriage of high temperatures and multiple materials, are revolutionizing diverse industries. Let's delve into the competitive landscape of this smoldering market, exploring the strategies, market share factors, industry news, and recent developments shaping its trajectory.

Strategies Adopted by Co-Fired Ceramic Titans:

-

Material Innovation: Companies like Murata, Kyocera, and TDK are constantly pushing boundaries with new material combinations. Think LTCC (low-temperature co-fired ceramics) with enhanced thermal and electrical properties, biocompatible ceramics for medical implants, and even micro-fluidic ceramics for lab-on-a-chip applications. -

Application Diversification: Beyond traditional electronics and telecommunications, companies are venturing into automotive sensors, medical devices, aerospace components, and even energy harvesting applications. This broadens market reach and caters to niche needs. -

Miniaturization and High-Density Integration: The shrinking size of electronic devices demands ever-smaller and more complex co-fired ceramic components. Companies are honing their micro-fabrication techniques and developing intricate multi-layered structures. -

Sustainability Push: Environmental consciousness is impacting the market. Companies are exploring lead-free and recyclable materials, implementing cleaner production processes, and minimizing energy consumption during co-firing. -

Vertical Integration: Gaining control over the supply chain is becoming crucial. Companies are acquiring raw material suppliers, processing facilities, and even downstream distributors to ensure stable pricing, product quality, and market reach.

Factors Influencing Market Share:

-

Technological Expertise: Possessing the knowledge and expertise to design, develop, and manufacture complex co-fired ceramic components with precise properties and functionalities is paramount. -

Quality and Reliability: Consistent high quality and reliable performance in demanding environments are essential for building trust and securing long-term partnerships. -

Cost-Effectiveness: Balancing advanced features with competitive pricing is crucial. Companies need to optimize production processes and offer flexible solutions to cater to diverse budget constraints. -

Innovation and R&D: Investing in research and development of new materials, fabrication techniques, and applications is key for staying ahead of the competition.

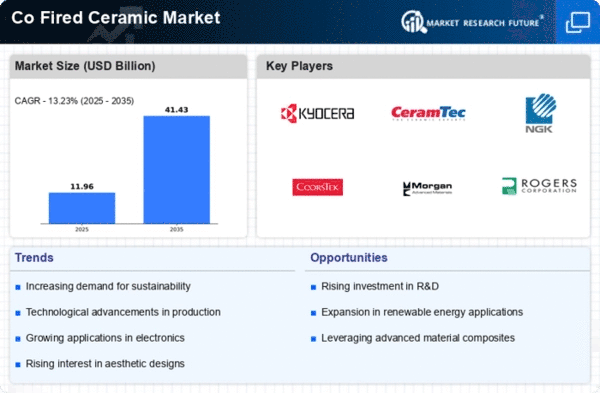

Key Players

-

DuPont (US)

-

Kyocera Corporation (Japan)

-

TDK Corporation (Japan)

-

KOA Corporation (Japan)

-

HitachiMetals, Ltd (Japan)

-

CeramTec (Germany)

-

Yokowo Co., Ltd (Japan)

-

Murata Manufacturing Co., Ltd (Japan)

-

NGK Spark Plug Co. Ltd (Japan)

-

Micro Systems Technologies (Switzerland)

-

Murawa Co. Ltd (Japan)

-

Nikko Company (Japan)

-

IMST GmbH (Germany)

-

API Technologies (UK)

-

Selmic Oy (Finland)

Recent Developments:

-

October 2023: Murata announces a breakthrough in 3D printing technology for co-fired ceramics, enabling the creation of previously impossible geometries. -

November 2023: The European Chemicals Agency proposes a ban on lead in certain electronics, potentially impacting the production of traditional LTCC materials. -

December 2023: A research team develops a new co-fired ceramic material with self-healing properties, promising longer lifespan and reduced maintenance needs.