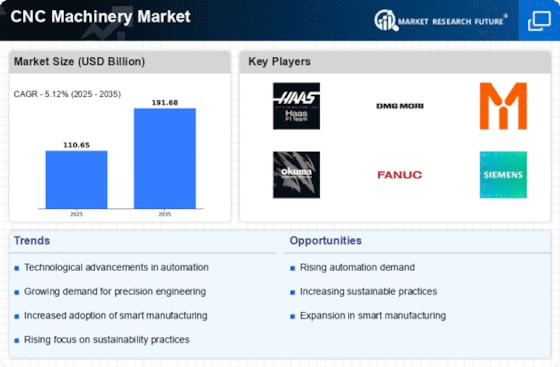

Rising Automation

The increasing trend towards automation in manufacturing is a key driver for the CNC Machinery Market. As companies strive to enhance efficiency and reduce labor costs, the adoption of CNC machinery is becoming more prevalent. Data indicates that the automation market is expected to grow at a compound annual growth rate of over 10% in the coming years. This shift towards automated solutions is prompting manufacturers to invest in CNC machinery that can operate autonomously, thereby increasing production rates and minimizing human error. Consequently, the CNC Machinery Market is poised for significant expansion as more businesses recognize the benefits of automation.

Technological Advancements

The CNC Machinery Market is experiencing rapid technological advancements that enhance precision and efficiency. Innovations such as artificial intelligence and machine learning are being integrated into CNC systems, allowing for smarter operations and predictive maintenance. According to recent data, the adoption of advanced CNC technologies is projected to increase productivity by up to 30%. This trend not only reduces operational costs but also improves product quality, making CNC machinery more appealing to manufacturers. As industries seek to optimize their production processes, the demand for technologically advanced CNC machinery is likely to rise, driving growth in the CNC Machinery Market.

Customization and Flexibility

The demand for customization in manufacturing processes is a notable driver of the CNC Machinery Market. As consumers increasingly seek personalized products, manufacturers are compelled to adopt CNC machinery that offers flexibility in design and production. This trend is reflected in market data, which shows that the customization segment is expected to account for a substantial share of the CNC machinery market. The ability to produce tailored solutions efficiently allows manufacturers to meet diverse customer needs while maintaining competitive pricing. Thus, the CNC Machinery Market is likely to see continued growth as businesses invest in versatile CNC systems that can adapt to changing market demands.

Focus on Quality and Precision

The emphasis on quality and precision in manufacturing processes is a critical driver for the CNC Machinery Market. As industries such as aerospace, automotive, and medical devices demand higher standards, the need for precise machining solutions becomes paramount. Market analysis indicates that the demand for high-precision CNC machinery is on the rise, with projections suggesting a growth rate of around 8% in this segment. This focus on quality not only enhances product reliability but also reduces waste and rework, making CNC machinery an essential component in achieving operational excellence. Consequently, the CNC Machinery Market is likely to expand as manufacturers prioritize precision in their production processes.

Increased Investment in Manufacturing

Investment in the manufacturing sector is a significant driver for the CNC Machinery Market. Governments and private entities are channeling funds into modernizing manufacturing facilities, which often includes upgrading to CNC machinery. Recent statistics reveal that manufacturing investment is projected to rise by approximately 5% annually, creating a favorable environment for CNC machinery adoption. This influx of capital enables manufacturers to enhance their production capabilities and improve operational efficiency. As a result, the CNC Machinery Market is expected to benefit from this trend, with increased demand for advanced CNC router solutions that support modern manufacturing practices.