Cnc Controller Size

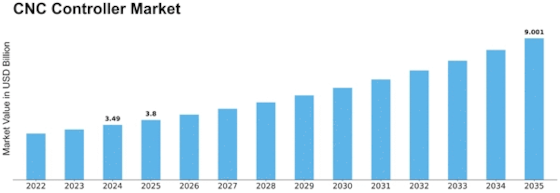

CNC Controller Market Growth Projections and Opportunities

Numerous market variables influence the CNC controller industry and generally determine its trajectory. The constant mechanical advancements in the assembly sector are one of the primary drivers. As efforts to increase precision, expertise, and automation increase, there is a growing need for advanced CNC controllers. One of the key factors driving market expansion is the ongoing development of these controllers, which combine features like varied control and continuous observation. To stay ahead of the serious scene, makers are investing resources in creative labor, which has led to an ongoing flood of inventive combinations. Businesses typically invest in improving their assembly skills during periods of financial expansion, which increases demand for CNC controllers. However, financial downturns may force a halt to contemporary speculation, which would affect the market. Comprehending and adapting to these economic cycles is essential for partners in the CNC controller industry to investigate trends. The quest for a more extensive item portfolio, upgraded mechanical capacities, and expanded topographical presence drives these activities. Joint efforts with machine device producers and end-clients are additionally normal techniques utilized by market players to set their positions and cultivate development. Modifications to these rules may result in adjustments to the design and functionality of CNC controllers, which may impact market components. Respecting international standards ensures the stability, security, and compatibility of CNC systems, enhancing their market value and longevity. Energy efficiency and controllability are becoming noticeable as important competitive elements. Manufacturers are increasingly focused on developing CNC controllers with components that are energy-efficient and do no harm to the environment. End users are demonstrating a preference for configurations that align with manageability goals, which is contributing to the development of more environmentally friendly CNC controllers. This trend is consistent with the broader industry drive toward dependable and affordable practice assembly. Conversely, developed economies encounter demand that is fueled by the replacement of outdated frameworks with more advanced CNC controllers, contributing to a distinct global market landscape. To fully realize the potential of intelligent assembly, CNC controllers must constantly collaborate with other advances in the field. Examples of these breakthroughs include mechanical engineering, sensors, and information analysis. Players in the market must continue to be sensitive to these mechanical advancements and ensure that their CNC controllers meet the evolving needs of digitally linked and networked biological systems that are manufactured. Customer preferences and industry-specific requirements play a major role in shaping the CNC controller market.

Leave a Comment