Market Trends

Key Emerging Trends in the Closed Cell Foam Market

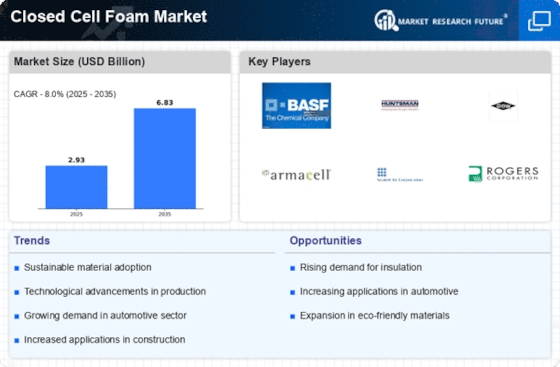

The Closed Cell Foam Market is currently experiencing dynamic trends that showcase the versatile applications of closed-cell foam materials across various industries. One significant trend is the increasing demand for closed-cell foam in the construction sector, particularly in insulation applications. Closed-cell foam exhibits excellent thermal insulation properties, making it a preferred choice for insulating buildings, pipelines, and HVAC systems. This trend aligns with the construction industry's emphasis on energy efficiency, sustainability, and the reduction of heat loss, contributing to the overall environmental performance of buildings.

Moreover, the automotive industry is a major contributor to the momentum in the Closed Cell Foam Market. Closed-cell foam finds applications in vehicle interiors for noise reduction, vibration damping, and thermal insulation. The material's ability to provide a lightweight and efficient solution for enhancing comfort and reducing noise in automobiles is driving its increased adoption by automotive manufacturers. This trend reflects the ongoing efforts in the automotive sector to improve vehicle acoustics, enhance passenger comfort, and meet stringent regulatory requirements related to noise and emissions.

Technological advancements in foam manufacturing processes are shaping market trends in the Closed Cell Foam Market. Innovations in extrusion, molding, and cutting technologies are optimizing the production of closed-cell foam products with precise specifications and performance characteristics. This trend is crucial for meeting the evolving needs of industries where closed-cell foam is applied, ensuring consistent quality and enhanced functionalities. The industry's focus on continuous innovation is driving the development of closed-cell foam solutions that cater to diverse applications.

The packaging industry's influence on closed-cell foam trends is substantial, with closed-cell foam materials being used for protective packaging and cushioning applications. The ability of closed-cell foam to provide shock absorption and impact resistance makes it a valuable material for protecting delicate and fragile goods during transportation. This trend aligns with the increasing demand for reliable and efficient packaging solutions across various sectors, including electronics, pharmaceuticals, and consumer goods.

Sustainability considerations are becoming increasingly important in shaping market dynamics in the Closed Cell Foam Market. Manufacturers are exploring sustainable sourcing of raw materials, eco-friendly production processes, and recyclable options for closed-cell foam products. This trend aligns with the broader industry movement towards environmentally responsible practices, reflecting the commitment to reducing the environmental impact of materials and meeting the growing demand for sustainable solutions.

E-commerce is playing a role in reshaping the distribution channels of closed-cell foam products. The convenience of online platforms for product discovery, comparison, and purchase is influencing buyer behavior in the industrial materials sector. Manufacturers and distributors are adapting to this trend by enhancing their online presence, providing detailed product information, and offering efficient delivery services. The accessibility of closed-cell foam products through e-commerce platforms contributes to increased market awareness and ease of procurement.

Regulatory considerations and adherence to safety standards are pivotal factors shaping market dynamics in the Closed Cell Foam Market. As closed-cell foam is used in critical applications, including construction, automotive, and packaging, compliance with regulations related to fire safety, performance, and environmental impact is crucial. Companies are investing in research and development to ensure that their closed-cell foam products meet or exceed regulatory requirements, providing assurances to industries that rely on these materials.

Strategic collaborations and partnerships are emerging as trends in the Closed Cell Foam Market. Companies are exploring synergies through joint ventures, alliances, and collaborations to enhance research, development, and commercialization efforts. The collaborative approach allows for the exchange of expertise, resources, and market insights, fostering innovation and ensuring the continuous growth of the closed-cell foam industry.

Leave a Comment