North America : Market Leader in Innovation

North America is the largest market for chemical injection skids, holding approximately 45% of the global market share. The region's growth is driven by increasing demand from the oil and gas sector, stringent environmental regulations, and advancements in technology. The U.S. leads this market, followed closely by Canada, which contributes around 20% to the overall chemical injection skid market. Regulatory support for efficient chemical management further fuels this growth.

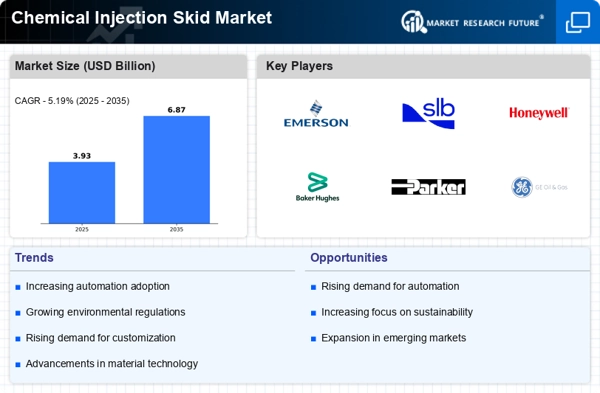

The competitive landscape in North America is robust, featuring key players such as Emerson Electric Co, Schlumberger Limited, and Honeywell International Inc. These companies are investing in innovative solutions to enhance efficiency and reduce environmental impact. The presence of established infrastructure and a focus on R&D are pivotal in maintaining the region's leadership in the chemical injection skid market.

Europe : Emerging Market with Regulations

Europe is witnessing significant growth in the chemical injection skid market, accounting for approximately 30% of the global share. The region's expansion is driven by increasing investments in renewable energy and stringent regulations aimed at reducing carbon emissions. Countries like Germany and the UK are at the forefront, with Germany holding about 15% of the chemical injection skid market. The European Union's commitment to sustainability is a key regulatory catalyst for this growth.

Leading countries in Europe include Germany, the UK, and France, with a competitive landscape featuring companies like KROHNE Group and Aalborg Instruments. The presence of these key players, along with a focus on innovative technologies, positions Europe as a significant player in the global chemical injection skid market. The region's regulatory framework encourages the adoption of advanced chemical injection systems, further enhancing market dynamics.

Asia-Pacific : Rapid Growth and Demand

Asia-Pacific is rapidly emerging as a significant player in the chemical injection skid market, holding around 20% of the global share. The region's growth is fueled by increasing industrialization, particularly in countries like China and India, where demand for efficient chemical management systems is on the rise. The region's focus on infrastructure development and energy efficiency is also a driving force behind this expansion.

China is the largest market in Asia-Pacific, contributing approximately 12% to the global market, followed by India. The competitive landscape is characterized by both local and international players, with companies like Baker Hughes and Parker Hannifin Corporation actively participating. The region's growing emphasis on technological advancements and sustainable practices is expected to further boost chemical injection skid market growth in the coming years.

Middle East and Africa : Resource-Rich Market Potential

The Middle East and Africa region is gradually developing its chemical injection skid market, currently holding about 5% of the global share. The growth is primarily driven by the oil and gas sector, which is a significant contributor to the region's economy. Countries like Saudi Arabia and the UAE are leading the chemical injection skid market, with a focus on enhancing operational efficiency and reducing environmental impact through advanced chemical management systems.

The competitive landscape in this region is evolving, with key players such as GE Oil & Gas and Baker Hughes establishing a strong presence. The region's vast natural resources and ongoing investments in infrastructure are expected to drive demand for chemical injection skids. As regulatory frameworks become more stringent, the chemical injection skid market is poised for growth, aligning with global sustainability trends.