Ceramic Membranes Size

Ceramic Membranes Market Growth Projections and Opportunities

The Ceramic Membranes market facing a lot of challenges and opportunities collectively determine its nature at large. Ceramic membranes are versatile infiltration systems which serve different industrial sectors such as water treatment, pharmaceuticals, as well as food and beverages, and biotechnology. One of the main factors for effective development of Ceramic Membranes business is the rising demand of such water treatment technologies that are considered to be efficient and eco-friendly. The product comes hand-in-hand with the emerging phenomenon of water deficit and the demand for reliable membrane systems delivering better filtration than the traditional ones, with increased durability and ability to work under harsh operating conditions.

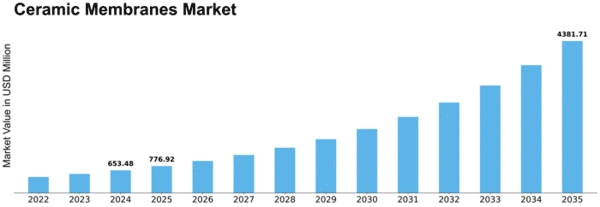

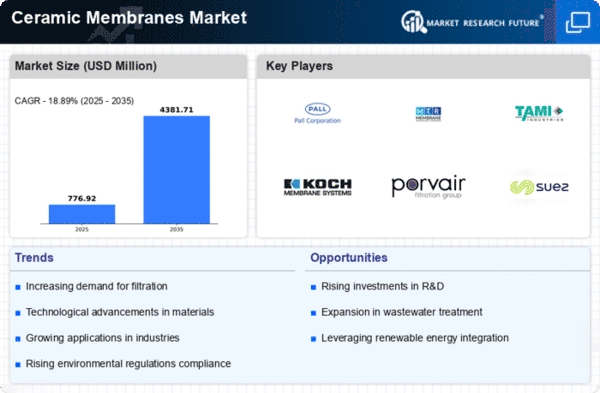

The valuation of Ceramic Membranes Market constituted of USD 9.9 Billion in 2022. As the world demands sustainability and clean energy, Ceramic Membranes market projected to reach USD 25.1 Billion in 2032, growing at a CAGR of 10.90% from the current level of USD 11.0 Billion in 2023.

Ceramic membrane technology is one of the crucial aspects of the market which keeps evolving thanks to manufacuring avant-gardes. Besides developing the fabrication processes that are based on the use of ceramic materials, the work of researchers concentrates on improving the properties of membranes and expanding the areas of applications for ceramic membranes. The next breakthroughs in the development of membranes are the membrane design, the pore size control, and the surface modifications that aim to enhance efficiency of filtration and focus on industry specific issues delivering to the end-users flexible products.

The role of regulations and standards issued by the government as an implement for the Ceramic Membranes market development can`t be overstated. Full adherence to the rules pertaining to water quality, wastewater discharge and the impact of the environment is a compulsory obligation of manufacturers. Adjustments of regulations, which could set the main accent on the sustainable water management and strict discharge standards can lead the market to the adoption of smart ceramic membrane products.

The global water crisis the industrialization trend can have an impact on Ceramic Membranes. Increased perception of water shortages, pollution and the availability of potable water treatment technologies are key influencers behind the adoption of ceramics membranes. Industries such as medicine, chemicals and food processing are putting resources into membrane technologies to meet the regulatory requisites and for improved sustainability of the operations.

This market is influenced by economic factors, namely, the emergence of industries and the infrastructural development. Stable economy, driving the funds raising and installation of effective membrane technologies is another cause for the increasing use of water and wastewater treatment. Contrary, financial slack or cyclicity in industrial operational cost will also bring market fluctuations as industries focus their expenditures on selecting various water treatment options.

Comprehensiveness of the Membrane technology, acting as a leader in the Ceramic Membranes market dynamics. One way manufacturers alike invest in R&D is developing scientific, industrial ceramic membrane products, upgrading manufacturing plants, and meeting growing industries’ filtration demands in a reliable way.

Leave a Comment