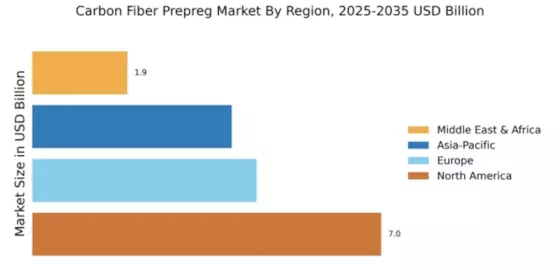

North America : Market Leader in Innovation

North America is poised to maintain its leadership in the Carbon Fiber Prepreg market, holding a significant market share of 7.0 in 2024. The region's growth is driven by increasing demand in aerospace, automotive, and renewable energy sectors, alongside supportive government regulations promoting advanced materials. The focus on lightweight and high-strength materials is further propelling market expansion, with innovations in manufacturing processes enhancing efficiency and reducing costs. The competitive landscape in North America is robust, featuring key players such as Toray Industries, Hexcel Corporation, and Zoltek Companies. The U.S. is the leading country, supported by a strong industrial base and significant investments in R&D. The presence of major manufacturers and a growing number of startups focused on carbon fiber technologies are expected to drive further growth, making North America a hub for innovation in this sector.

Europe : Emerging Market with Potential

Europe is witnessing a growing interest in the Carbon Fiber Prepreg market, with a market size of 4.5. The region's growth is fueled by increasing applications in the automotive and aerospace industries, driven by stringent regulations aimed at reducing emissions and enhancing fuel efficiency. The European Union's commitment to sustainability and innovation is acting as a catalyst for the adoption of advanced materials, including carbon fiber prepregs, which are essential for lightweight construction. Leading countries in Europe include Germany, France, and the UK, where major players like SGL Carbon and Cytec Solvay Group are actively investing in new technologies. The competitive landscape is characterized by collaborations between manufacturers and research institutions, fostering innovation. The presence of a skilled workforce and advanced manufacturing capabilities further strengthens Europe's position in the global market.

Asia-Pacific : Rapid Growth and Adoption

Asia-Pacific is rapidly emerging as a significant player in the Carbon Fiber Prepreg market, with a market size of 4.0. The region's growth is driven by increasing demand from the automotive and aerospace sectors, particularly in countries like China and Japan. Government initiatives promoting the use of lightweight materials to enhance energy efficiency are further propelling market growth. The region is also witnessing a rise in manufacturing capabilities, making it a competitive landscape for carbon fiber production. China is the leading country in the region, supported by major manufacturers such as Mitsubishi Chemical Corporation and Teijin Limited. The competitive environment is characterized by a mix of established players and new entrants, focusing on innovation and cost-effective production methods. As the demand for carbon fiber prepregs continues to rise, Asia-Pacific is expected to play a crucial role in the global market dynamics.

Middle East and Africa : Untapped Market Opportunities

The Middle East and Africa region is currently at a nascent stage in the Carbon Fiber Prepreg market, with a market size of 1.91. However, there are significant opportunities for growth driven by increasing investments in infrastructure and aerospace sectors. The region's focus on diversifying its economy away from oil dependency is leading to a growing interest in advanced materials, including carbon fiber prepregs, which are essential for modern manufacturing processes. Countries like South Africa and the UAE are beginning to explore the potential of carbon fiber applications, supported by government initiatives aimed at fostering innovation. The competitive landscape is still developing, with a few key players starting to establish a presence. As the market matures, the region is expected to attract more investments and partnerships, paving the way for future growth in the carbon fiber sector.