Expansion in Automotive Industry

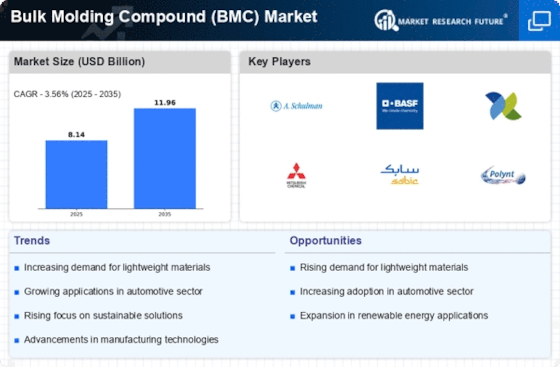

The Bulk Molding Compound Market (BMC) Market is poised for growth due to the expansion of the automotive industry. With the increasing focus on lightweight materials to improve fuel efficiency and reduce emissions, BMC is becoming a preferred choice for various automotive components, including body panels, electrical housings, and structural parts. The automotive sector is anticipated to witness a CAGR of around 4% in the coming years, which may drive the demand for BMC. Additionally, the shift towards electric vehicles (EVs) is likely to create new opportunities for BMC applications, as these vehicles require materials that can meet stringent safety and performance standards. Thus, the BMC Market stands to gain from the automotive sector's evolution.

Growth in Renewable Energy Applications

The Bulk Molding Compound Market (BMC) Market is benefiting from the growth in renewable energy applications. As the world shifts towards sustainable energy sources, the demand for components used in wind turbines, solar panels, and other renewable technologies is increasing. BMC's excellent mechanical properties and resistance to environmental factors make it suitable for these applications. The renewable energy sector is expected to grow at a CAGR of approximately 8% in the next few years, which could significantly impact the BMC Market. Manufacturers are likely to explore BMC for its potential to enhance the durability and efficiency of renewable energy systems, thereby driving further adoption.

Increasing Focus on Lightweight Materials

The Bulk Molding Compound Market (BMC) Market is witnessing a growing emphasis on lightweight materials across various sectors. Industries are increasingly recognizing the benefits of using lightweight compounds to improve efficiency and reduce energy consumption. BMC, known for its strength-to-weight ratio, is becoming a preferred material in sectors such as aerospace, automotive, and construction. The trend towards lightweight materials is projected to grow at a CAGR of around 6% in the coming years, which may positively influence the BMC Market. As companies strive to enhance performance while minimizing weight, the demand for BMC is likely to rise, reflecting a broader industry shift towards innovative material solutions.

Rising Demand in Electrical and Electronics Sector

The Bulk Molding Compound Market (BMC) Market is experiencing a notable surge in demand driven by the electrical and electronics sector. As industries increasingly adopt lightweight and durable materials, BMC's properties make it an attractive choice for manufacturing components such as connectors, insulators, and housings. The electrical and electronics sector is projected to grow at a compound annual growth rate (CAGR) of approximately 5% over the next few years, which could further bolster the BMC market. This growth is attributed to the ongoing trend of miniaturization and the need for materials that can withstand high temperatures and electrical stress. Consequently, the BMC Market is likely to benefit from this trend, as manufacturers seek materials that enhance performance while reducing weight.

Technological Innovations in Manufacturing Processes

The Bulk Molding Compound Market (BMC) Market is experiencing a transformation due to technological innovations in manufacturing processes. Advances in production techniques, such as improved molding technologies and automation, are enhancing the efficiency and quality of BMC products. These innovations are expected to reduce production costs and lead times, making BMC more competitive against alternative materials. The manufacturing sector is projected to grow at a CAGR of approximately 5% in the next few years, which could further stimulate the BMC Market. As manufacturers adopt these new technologies, the potential for increased production capacity and product customization may drive further growth in the BMC market.