Market Analysis

In-depth Analysis of Brown Fused Alumina Market Industry Landscape

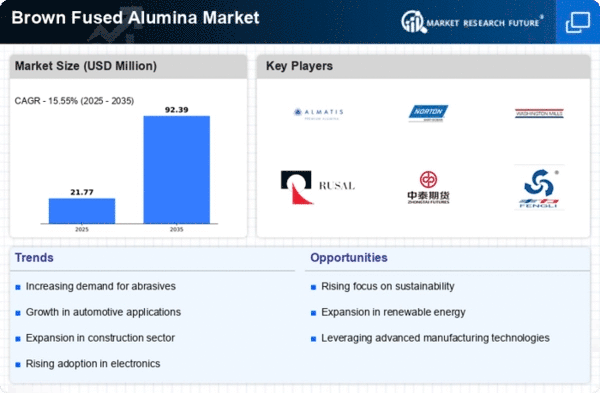

The brown fused alumina market operates within a dynamic framework influenced by various factors that shape its growth and evolution. Brown fused alumina, also known as brown aluminum oxide, is a versatile abrasive material widely used in grinding wheels, sandpaper, blasting media, and refractory applications. One of the primary drivers of market dynamics is the increasing demand from the abrasive industry. Brown fused alumina is prized for its hardness, toughness, and abrasive properties, making it ideal for cutting, grinding, and surface finishing applications across various industries such as metalworking, automotive, construction, and aerospace. As these industries continue to expand and innovate, the demand for brown fused alumina is expected to grow, driving market growth.

Technological advancements play a crucial role in shaping the competitive landscape of the brown fused alumina market. Innovations in manufacturing processes, product formulations, and abrasive technologies have led to improvements in product quality, performance, and efficiency. Advanced production techniques such as electric arc furnaces and rotary kilns allow manufacturers to produce high-quality brown fused alumina with precise chemical compositions and particle sizes. Moreover, the development of new bonding systems and abrasive coatings enhances the performance and versatility of brown fused alumina products, offering opportunities for market players to differentiate their offerings and cater to specific customer needs.

Market dynamics in the brown fused alumina industry are also influenced by economic factors such as industrial production, construction activity, and global manufacturing trends. Economic growth and industrial expansion drive demand for abrasive materials used in metal fabrication, surface preparation, and construction applications. Conversely, economic downturns or recessions may lead to reduced demand for brown fused alumina as industries scale back production and capital expenditures. Moreover, fluctuations in commodity prices, currency exchange rates, and trade policies can impact the cost of raw materials and affect the profitability of brown fused alumina manufacturers operating in the global market.

Environmental regulations and sustainability concerns are increasingly shaping the dynamics of the brown fused alumina market. Abrasive manufacturing processes can generate emissions, waste, and environmental pollutants if not properly managed. As a result, governments and regulatory bodies are implementing stricter environmental regulations to reduce emissions, improve waste management practices, and promote sustainable production in the abrasive industry. Brown fused alumina manufacturers are investing in technologies and practices to minimize environmental impact, such as adopting cleaner production processes, recycling abrasive waste, and reducing energy consumption. Additionally, there is a growing demand for eco-friendly abrasive materials and products that minimize dust emissions and environmental contamination, driving innovation and market growth in sustainable abrasive solutions.

Customer preferences and industry trends also influence market dynamics in the brown fused alumina sector. End-users are increasingly seeking abrasive materials that offer high performance, durability, and cost-effectiveness for their applications. Industry trends such as automation, digitization, and Industry 4.0 are driving the demand for advanced abrasive solutions that improve productivity, reduce processing times, and enhance product quality. Furthermore, the shift towards lightweight materials, composite materials, and advanced alloys in manufacturing and aerospace industries is creating new opportunities for brown fused alumina manufacturers to supply abrasive products tailored to these applications.

The competitive dynamics within the brown fused alumina market are characterized by intense rivalry among key players competing for market share and profitability. Market participants range from large multinational abrasive companies to smaller regional manufacturers and distributors. Strategies such as vertical integration, product differentiation, and geographic expansion are commonly employed by companies to strengthen their market position and differentiate themselves from competitors. Additionally, quality assurance, technical support, and customer service initiatives are essential for companies to maintain customer satisfaction and retain their competitive edge in a highly competitive market environment.

Leave a Comment