Growing Focus on Customization

The Boring Milling Machine Market is witnessing a growing focus on customization and flexibility in manufacturing processes. As customer demands become more diverse, manufacturers are increasingly seeking boring milling machines that can be tailored to specific applications. This trend is evident in sectors such as aerospace and automotive, where unique specifications are commonplace. Recent Market Research Future indicate that the customization segment is expected to grow by approximately 5% annually, reflecting the industry's shift towards personalized solutions. Consequently, manufacturers are investing in versatile boring milling machines that can accommodate a wide range of materials and designs, thereby enhancing their operational capabilities and market competitiveness.

Sustainability and Energy Efficiency

Sustainability is becoming a critical driver in the Boring Milling Machine Market. As environmental concerns rise, manufacturers are increasingly prioritizing energy-efficient and sustainable machining solutions. The demand for machines that minimize waste and reduce energy consumption is on the rise, with studies indicating that energy-efficient boring milling machines can reduce operational costs by up to 30%. This shift towards sustainability is not only beneficial for the environment but also aligns with regulatory requirements and consumer preferences. As a result, manufacturers are compelled to invest in eco-friendly boring milling technologies, which is likely to foster growth in the market as companies seek to enhance their sustainability profiles.

Expansion of the Manufacturing Sector

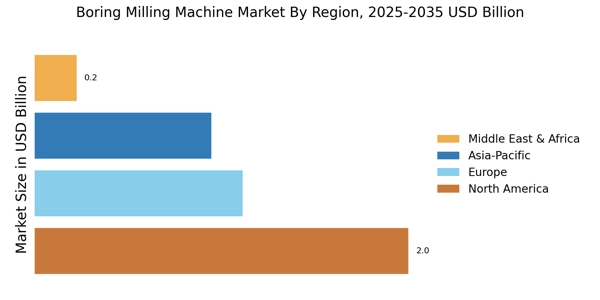

The Boring Milling Machine Market is poised for growth due to the ongoing expansion of the manufacturing sector. As countries invest in infrastructure and industrial development, the demand for efficient machining solutions is escalating. Recent statistics indicate that the manufacturing sector is expected to witness a growth rate of around 4% annually, which directly correlates with the increased adoption of boring milling machines. This trend is particularly evident in emerging markets, where industrialization efforts are driving the need for advanced machining technologies. As manufacturers seek to optimize production processes and reduce operational costs, the adoption of sophisticated boring milling machines becomes a strategic imperative, thereby propelling the market forward.

Rising Demand for Precision Engineering

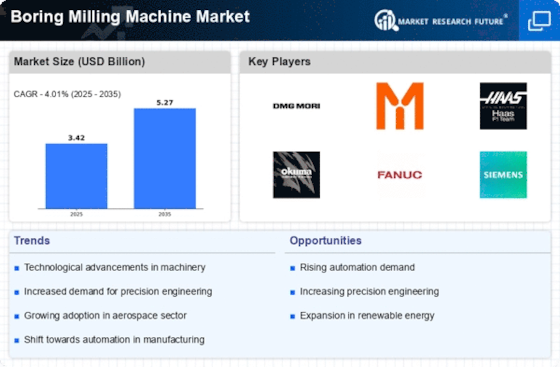

The Boring Milling Machine Market is experiencing a notable surge in demand for precision engineering across various sectors, including aerospace, automotive, and manufacturing. As industries increasingly prioritize accuracy and efficiency, the need for advanced boring milling machines that can deliver high precision is becoming paramount. According to recent data, the market for precision engineering tools is projected to grow at a compound annual growth rate of approximately 6.5% over the next five years. This growth is likely to drive investments in innovative boring milling technologies, enhancing the capabilities of these machines to meet stringent quality standards. Consequently, manufacturers are compelled to adopt state-of-the-art boring milling machines to maintain competitiveness and meet customer expectations.

Technological Innovations in Machine Tools

Technological innovations are significantly influencing the Boring Milling Machine Market. The advent of smart manufacturing and Industry 4.0 is reshaping the landscape of machine tools, including boring milling machines. Enhanced automation, integration of artificial intelligence, and the Internet of Things are transforming traditional machining processes. For instance, the introduction of CNC (Computer Numerical Control) boring milling machines has revolutionized precision and efficiency in machining operations. Market analysis suggests that the integration of these technologies could lead to a 20% increase in productivity for manufacturers. As companies strive to remain competitive, the adoption of technologically advanced boring milling machines is likely to accelerate, driving market growth.