Cost Efficiency in Production

The Binder Jetting 3D Printing Technology Market is experiencing a notable shift towards cost efficiency in production processes. This technology allows for the rapid production of complex geometries with minimal material waste, which is particularly appealing to manufacturers aiming to reduce operational costs. The ability to produce parts without the need for extensive tooling or molds further enhances its cost-effectiveness. Recent data indicates that companies utilizing binder jetting can achieve up to 50% savings in material costs compared to traditional manufacturing methods. As industries seek to optimize their production lines, the adoption of binder jetting technology is likely to increase, driving growth in the market.

Integration with Industry 4.0

The Binder Jetting 3D Printing Technology Market is poised for growth through its integration with Industry 4.0 principles. The rise of smart manufacturing and the Internet of Things (IoT) is transforming production environments, and binder jetting technology is well-positioned to benefit from these advancements. By incorporating data analytics and automation, manufacturers can optimize their binder jetting processes, leading to improved efficiency and reduced downtime. The potential for real-time monitoring and predictive maintenance enhances the overall productivity of manufacturing operations. As industries increasingly embrace digital transformation, the binder jetting market is likely to expand, driven by the demand for more intelligent and connected manufacturing solutions.

Advancements in Material Science

The Binder Jetting 3D Printing Technology Market is significantly influenced by advancements in material science. The development of new binders and powders has expanded the range of materials that can be used in binder jetting processes, including metals, ceramics, and composites. This diversification allows for the production of parts with enhanced mechanical properties and performance characteristics. For instance, recent innovations have led to the creation of high-strength metal alloys that can be processed using binder jetting, which was previously challenging. As material options continue to evolve, the market is expected to witness increased adoption across various sectors, including aerospace and automotive, where material performance is critical.

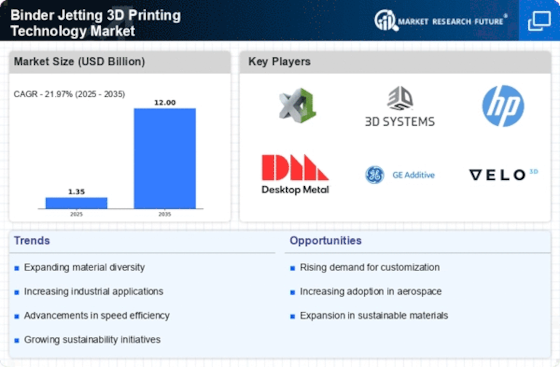

Growing Demand for Customization

The Binder Jetting 3D Printing Technology Market is witnessing a surge in demand for customization and personalization in manufacturing. As consumers increasingly seek tailored products, industries are turning to binder jetting technology to meet these needs. This method allows for the efficient production of unique designs and specifications without the need for extensive retooling. Recent market analysis suggests that the customization trend is driving a significant portion of the growth in the binder jetting sector, with projections indicating a potential increase in market size by over 20% in the coming years. This capability to produce bespoke items positions binder jetting as a key player in the evolving landscape of manufacturing.

Sustainability and Environmental Considerations

The Binder Jetting 3D Printing Technology Market is increasingly aligned with sustainability and environmental considerations. As industries face pressure to reduce their carbon footprint, binder jetting offers a more sustainable alternative to traditional manufacturing methods. The process generates less waste and utilizes fewer resources, which is appealing to environmentally conscious companies. Furthermore, the ability to recycle unused powder materials in binder jetting processes contributes to its sustainability profile. Recent studies indicate that companies adopting this technology can reduce their environmental impact by up to 30%. This alignment with sustainability goals is likely to drive further adoption of binder jetting technology across various sectors.