Expansion of Emerging Markets

Emerging markets are becoming increasingly influential in the Bearing Industry. Rapid industrialization and urbanization in regions such as Asia-Pacific and Latin America are driving the demand for bearings across various sectors, including automotive, aerospace, and manufacturing. As these economies continue to grow, the need for infrastructure development and transportation solutions is expected to rise, further fueling the magnet bearing. Companies are strategically positioning themselves to capitalize on these opportunities by establishing manufacturing facilities and distribution networks in these regions, thereby enhancing their market presence and catering to local demands.

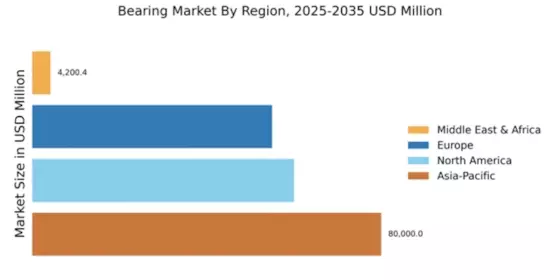

Market Trends and Projections

The Bearing Industry is projected to experience substantial growth over the next decade. With a market value of 199.2 USD Billion in 2024, it is anticipated to reach 488.8 USD Billion by 2035, reflecting a compound annual growth rate of 8.5% from 2025 to 2035. This growth trajectory indicates a robust demand across various sectors, driven by technological advancements, increasing industrial automation, and the expansion of emerging markets. The market dynamics suggest a favorable environment for manufacturers and suppliers of automotive bearings, as they adapt to evolving customer needs and invest in innovative bearing solutions.

Increasing Industrial Automation

The trend towards industrial automation is a critical driver of the Bearing Market. As manufacturers seek to enhance productivity and reduce operational costs, the integration of automated systems becomes essential. Bearings play a vital role in the smooth operation of machinery and equipment used in automated processes. The increasing adoption of robotics and automated guided vehicles in various industries, including manufacturing and logistics, is likely to propel the demand for high-performance bearings. This shift towards automation not only boosts efficiency but also necessitates the development of advanced bearing technologies that can withstand the rigors of continuous operation.

Growth in Renewable Energy Sector

The Bearing Industry is poised to benefit from the expanding renewable energy sector. As countries worldwide invest in wind and solar energy, the demand for specialized bearings that can operate efficiently in harsh environments is increasing. Steel Wind Tower, for instance, require robust bearings to ensure longevity and reliability. This sector's growth is likely to contribute significantly to the market's expansion, as renewable energy installations continue to proliferate. The emphasis on sustainability and reducing carbon footprints further drives the demand for efficient bearing solutions, aligning with global efforts to transition towards cleaner energy sources.

Rising Demand in Automotive Sector

The Bearing Market experiences a notable surge in demand driven by the automotive sector. As electric vehicles gain traction, the need for high-performance bearings that can withstand increased loads and temperatures becomes paramount. In 2024, the market is valued at 199.2 USD Billion, with projections indicating a growth trajectory that could see it reach 488.8 USD Billion by 2035. This growth is underpinned by a compound annual growth rate of 8.5% from 2025 to 2035. Manufacturers are increasingly focusing on developing specialized bearings that enhance efficiency and reduce friction, thereby supporting the automotive industry's transition towards sustainability.

Technological Advancements in Manufacturing

Technological innovations in manufacturing processes significantly influence the Bearing Market. Advanced techniques such as additive manufacturing and precision machining allow for the production of bearings with enhanced performance characteristics. These advancements not only improve the durability and reliability of bearings but also enable customization to meet specific application requirements. As industries increasingly adopt automation and smart manufacturing practices, the demand for high-quality bearings is expected to rise. This trend aligns with the overall market growth, as manufacturers strive to meet the evolving needs of various sectors, including aerospace, construction, and energy.