Top Industry Leaders in the Bagging Machine Market

*Disclaimer: List of key companies in no particular order

Top listed global companies in the industry are:

- Tokyo Automatic Machinery Works Ltd. (Japan)

- Honeywell International Inc. (US)

- Syntegon Technology (Germany)

- All-Fill Incorporated (US)

- Payper S.A. (Spain)

- Bossar Packaging S.A. (Spain)

- Pakona Engineers Pvt. Ltd. (India)

- Concetti S.P.A. (Italy)

- Omori Machinery Co. Ltd. (Japan)

- Fres-co System USA Inc. (US), and others.

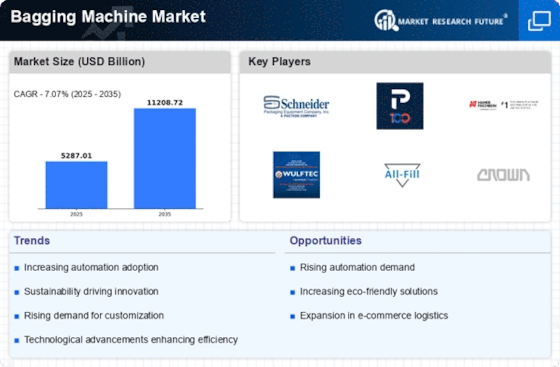

Sealing the Deal: Analyzing the Competitive Landscape of the Bagging Machine Market

The global bagging machine market is a fiercely competitive arena where players fight for their slice of the packaging pie. Understanding the strategies deployed to secure market share, the factors influencing success, and emerging trends is crucial for navigating this dynamic landscape.

Key Players and their Strategies:

- Global Giants: Industry titans like Syntegon and Bosch Packaging Technology leverage their extensive product portfolios, global reach, and brand recognition to maintain a prominent position. Syntegon offers diverse solutions across applications, while Bosch excels in high-speed and intelligent bagging systems.

- Regional Champions: Companies like Ishida Europe and Yamato Scale dominate specific regions by tailoring solutions to local regulations and industry needs. Ishida caters to Europe's stringent packaging standards, while Yamato excels in cost-effective solutions for emerging markets.

- Innovative Upstarts: Startups like tna solutions and Pack O'Matic disrupt the market with fresh approaches. tna focuses on flexible and modular bagging systems, while Pack O'Matic pushes the boundaries with robotics-integrated, high-precision solutions.

Factors for Market Share Analysis:

- Product Breadth and Depth: Offering a range of bagging machines for diverse applications (pouch filling, valve bagging, open mouth) and bag types (plastic, paper) caters to varied customer needs and expands market reach.

- Technological Innovation: Integrating advanced features like automation, high-speed operation, and digital controls enhances efficiency, accuracy, and integration with production lines. Bosch's intelligent bagging systems illustrate this.

- Cost-Effectiveness and ROI: Balancing advanced features with affordability is crucial, especially in budget-conscious segments. Yamato's cost-effective solutions have secured a strong foothold in emerging markets.

- After-Sales Service and Support: Offering comprehensive after-sales support, including installation, maintenance, and spare parts, fosters customer loyalty and market penetration. Syntegon excels in this area with its global service network.

Emerging Trends and Company Strategies:

- Smart Bagging Systems: Integrating sensors, communication modules, and AI into bagging machines enables real-time performance monitoring, predictive maintenance, and data-driven optimization. tna solutions' connected bagging systems exemplify this trend.

- Focus on Sustainability: Developing bagging machines with eco-friendly materials, minimized energy consumption, and reduced waste generation is gaining traction. Pack O'Matic's use of recycled materials exemplifies this approach.

- Customization and Flexibility: Offering modular and easily configurable bagging solutions caters to diverse product formats and changing production needs. Syntegon's modular platforms exemplify this approach.

- E-commerce Integration: Tailoring bagging machines to meet the specific needs of e-commerce fulfillment, such as high-speed and personalized packaging, is a growing trend. Yamato's solutions for e-commerce applications illustrate this approach.

Overall Competitive Scenario:

The bagging machine market presents a dynamic landscape where established players face challenges from regional specialists and technology-driven startups. Success hinges on offering diverse and technologically advanced solutions, balancing affordability with innovation, prioritizing service and support, and adapting to emerging trends like smart technologies, sustainability, and customization. Companies demonstrating agility, industry-specific expertise, and a commitment to responsible packaging practices hold a strong hand in securing their piece of the bagging market's future.

Latest Company Updates:

February 2023

Harpak-ULMA, one of the most prominent players in the smart and connected packaging solutions industry, has declared that its Tight-BagTM machines for poultry products are now available in North America. Many food products can have their hoover bagging automated by using Tight-Bag technology, which combines vertical bagging with an innovative, patented air extraction process.

The HMI-adjustable air volume and leakproof, perforation-free bags produced by the Tight-Bag machine enable up to 15% more bags per case for certain products. Known as Tight-ChickenTM, the Tight-Bag solution for poultry products eliminates the hygienic hazards that come with manual operations by combining automated product loading and vertical bagging to replace labor-intensive processes that are often involved in bagging fresh poultry.

In order to seal each bag to the required level of air content, the Tight-Bag process first forms film around the vertical tube that delivers the product. Next, it makes use of specialized cross-sealing jaws in conjunction with venturi air evacuation. A wide range of packaging films, including the breathable film used in certain applications involving fresh, crust-chilled poultry, can be fed into the machine.

To guarantee that there is no chance of leaks and that the product reaches stores in accordance with relevant hygiene regulations, Tight-Chicken makes sure that every bag fits the product like a second skin. Furthermore, the machine's design increases its production yield by up to 35 high-quality, leakproof bags per minute while reducing the processing line's footprint by doing away with separate vacuum chambers and bagging stations.