Market Trends

Key Emerging Trends in the Automotive Elastomers Market

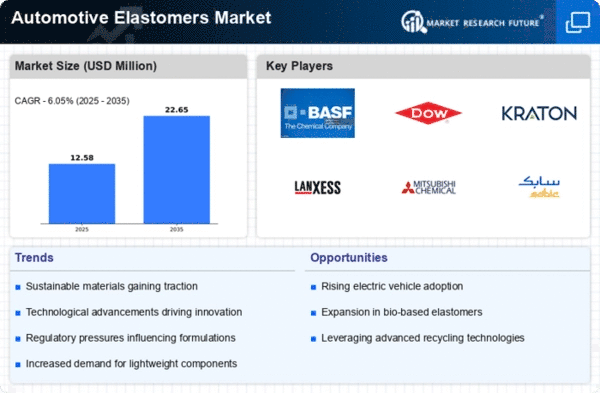

The Automotive Elastomers Market is subject to various market dynamics, influenced by trends that shape its growth and evolution:

Growing Demand for Lightweight Materials: One prominent trend in the automotive elastomers market is the increasing demand for lightweight materials to enhance fuel efficiency and reduce emissions in vehicles. Automakers are increasingly replacing traditional metal parts with elastomeric materials to achieve weight reduction without compromising on performance or safety standards.

Rising Adoption of Electric Vehicles (EVs): With the rise in environmental consciousness and government initiatives to curb carbon emissions, there's a growing adoption of electric vehicles. Automotive elastomers play a crucial role in EVs, providing insulation, sealing, and vibration dampening in critical components like batteries, motors, and charging systems, driving their demand in the market.

Focus on Comfort and Noise Reduction: Automotive manufacturers are prioritizing comfort and noise reduction in vehicles to enhance the driving experience. Elastomeric materials are used for noise and vibration dampening, as well as for sealing applications in doors, windows, and interiors, contributing to a quieter and more comfortable cabin environment, reflecting a significant trend in the automotive elastomers market.

Advancements in Material Technologies: Technological advancements in elastomer formulations and processing techniques are driving innovation in the automotive elastomers market. Manufacturers are developing high-performance elastomeric materials with improved durability, heat resistance, and chemical resistance to meet the demanding requirements of modern vehicles, aligning with market trends towards enhanced performance and reliability.

Shift towards Sustainable Solutions: Sustainability is a growing trend in the automotive industry, leading to the adoption of sustainable materials and manufacturing processes. Automotive elastomer manufacturers are responding to this trend by developing bio-based elastomers, recycling elastomeric materials, and implementing eco-friendly production methods, reflecting a shift towards sustainable solutions in the market.

Increasing Vehicle Customization: Consumer preferences for personalized vehicles are driving the trend towards vehicle customization. Automotive elastomers offer design flexibility, allowing for the customization of vehicle aesthetics through colored, textured, and molded elastomeric components such as trims, seals, and gaskets, catering to the demand for personalized vehicle experiences.

Emergence of Autonomous Vehicles: The development of autonomous vehicles is reshaping the automotive industry, with implications for elastomer applications. Automotive elastomers play a role in sensor housing, sealing, and insulation for autonomous vehicle components, contributing to the evolving landscape of the automotive elastomers market.

Growing Urbanization and Mobility Services: Increasing urbanization and the rise of mobility services such as ride-sharing and car-sharing are influencing vehicle design and usage patterns. Automotive elastomers are used in vehicle components like tires, seals, and suspension systems to withstand urban driving conditions and frequent use, reflecting market trends towards urban mobility solutions.

Supply Chain Disruptions and Resilience: The automotive elastomers market is susceptible to supply chain disruptions caused by factors such as natural disasters, geopolitical tensions, and pandemics. Manufacturers are implementing supply chain resilience strategies to mitigate risks and ensure the uninterrupted supply of elastomeric materials to meet market demand.

Regulatory Compliance and Standards: Compliance with regulatory standards regarding vehicle safety, emissions, and material usage is a key factor shaping the automotive elastomers market. Manufacturers must ensure that elastomeric materials meet regulatory requirements and industry standards for performance, durability, and environmental impact, influencing market dynamics and product development trends.

Leave a Comment