Growing Focus on Miniaturization

The trend towards miniaturization in electronic devices is a key driver of the Automatic Mounter Wafer Equipment Market. As manufacturers strive to produce smaller, more efficient components, the demand for precise mounter equipment increases. This miniaturization trend is particularly evident in the smartphone and wearable technology sectors, where space constraints necessitate advanced manufacturing techniques. In 2025, the market for miniaturized electronic components is expected to exceed 300 billion USD, further emphasizing the need for sophisticated automatic mounter wafer equipment. Manufacturers are thus compelled to invest in cutting-edge technologies that facilitate the production of smaller components without compromising quality, thereby fueling growth in the Automatic Mounter Wafer Equipment Market.

Expansion of Electric Vehicle Market

The expansion of the electric vehicle (EV) market significantly influences the Automatic Mounter Wafer Equipment Market. As the automotive industry shifts towards electrification, the demand for advanced semiconductor components increases. Electric vehicles require sophisticated electronic systems for battery management, power distribution, and infotainment, all of which rely on high-quality semiconductor devices. In 2025, the EV market is projected to grow to over 800 billion USD, creating substantial opportunities for manufacturers of automatic mounter wafer equipment. This growth necessitates the adoption of advanced mounter technologies to ensure efficient production of the required semiconductor components, thereby driving the Automatic Mounter Wafer Equipment Market.

Rising Demand for Semiconductor Devices

The increasing demand for semiconductor devices across various sectors, including consumer electronics, automotive, and telecommunications, drives the Automatic Mounter Wafer Equipment Market. As industries continue to adopt advanced technologies, the need for efficient and precise semiconductor manufacturing processes becomes paramount. In 2025, the semiconductor market is projected to reach approximately 600 billion USD, indicating a robust growth trajectory. This surge necessitates the deployment of automatic mounter wafer equipment to enhance production efficiency and reduce operational costs. Consequently, manufacturers are investing in advanced mounter technologies to meet the escalating demand, thereby propelling the Automatic Mounter Wafer Equipment Market forward.

Technological Advancements in Equipment

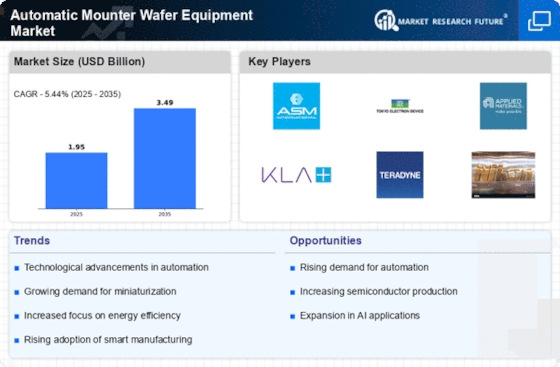

Technological advancements play a crucial role in shaping the Automatic Mounter Wafer Equipment Market. Innovations such as improved automation, enhanced precision, and integration of artificial intelligence are transforming the manufacturing landscape. These advancements enable manufacturers to achieve higher yields and reduce defects in semiconductor production. For instance, the introduction of smart mounters equipped with real-time monitoring capabilities allows for immediate adjustments during the manufacturing process. As a result, the market for automatic mounter wafer equipment is expected to grow significantly, with estimates suggesting a compound annual growth rate of around 8% over the next five years. This trend underscores the importance of staying at the forefront of technology to remain competitive in the Automatic Mounter Wafer Equipment Market.

Increased Investment in Research and Development

Investment in research and development (R&D) is a significant driver of the Automatic Mounter Wafer Equipment Market. Companies are increasingly allocating resources to innovate and enhance their manufacturing processes. This focus on R&D aims to develop more efficient mounter technologies that can handle complex designs and higher volumes. In 2025, it is anticipated that R&D spending in the semiconductor sector will reach approximately 80 billion USD, reflecting a commitment to advancing manufacturing capabilities. This investment not only fosters innovation but also positions companies to better meet the evolving demands of the market, thereby contributing to the growth of the Automatic Mounter Wafer Equipment Market.