Aseptic Packaging Size

Market Size Snapshot

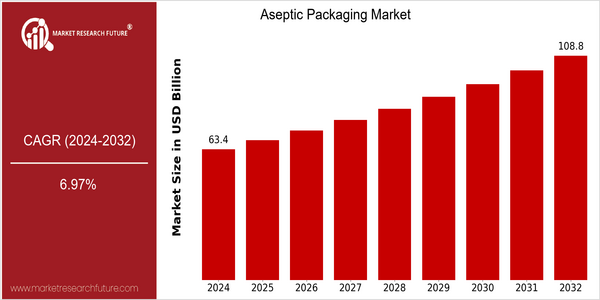

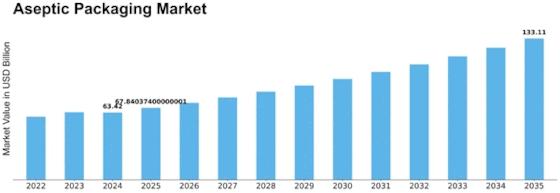

| Year | Value |

|---|---|

| 2024 | USD 63.42 Billion |

| 2032 | USD 108.75 Billion |

| CAGR (2024-2032) | 6.97 % |

Note – Market size depicts the revenue generated over the financial year

The aseptic package market is a growing market. The aseptic package market is expected to grow from 63,421 million in 2024 to 108,750,000 in 2032. This growth is a strong CAGR of 6.97% during the forecast period. The increasing demand for convenient and long-lasting food and beverages, combined with the growing awareness of food safety and hygiene, is driving the growth of the aseptic package market. In addition, the development of new packaging technology, such as the development of biodegradable materials and smart packaging solutions, will further increase the application of aseptic packaging in various industries, such as dairy, juice and ready-to-eat food. The key players in the aseptic package industry, such as Tetra Pak, SIG Combibloc and Elopak, are actively investing in innovation and strategic cooperation to enhance their market positions. Tetra Pak has launched a new biodegradable and compostable aseptic package. SIG Combibloc has introduced aseptic carton packages to meet the growing demand for plant-based beverages. These strategic initiatives not only reflect the commitment of the companies to innovation, but also meet the consumers' demands for sustainable and safe products.

Regional Market Size

Regional Deep Dive

Aseptic Packaging Market is experiencing a significant growth, driven by the rising demand for ready-to-drink beverages, food and pharmaceuticals. North America is characterized by high technological development and strict food safety regulations, while Europe is characterized by a focus on eco-friendly and sustainable packaging solutions. Asia-Pacific is characterized by rapid urbanization and changing lifestyles, which leads to an increase in demand for aseptic packaging. In the Middle East and Africa, investments in food processing and packaging technology are increasing, while in Latin America, food preservation and waste reduction are the main priorities.

Europe

- The European Union has introduced regulations aimed at reducing plastic waste, leading to increased demand for recyclable and biodegradable aseptic packaging materials.

- Companies such as Elopak and Stora Enso are pioneering developments in plant-based packaging solutions, aligning with the region's commitment to sustainability and reducing carbon footprints.

Asia Pacific

- Rapid urbanization in countries like India and China is driving the demand for ready-to-eat meals and beverages, significantly boosting the aseptic packaging market.

- Innovations in smart packaging technologies, such as temperature-sensitive labels, are being developed by companies like Amcor to enhance consumer safety and product quality.

Latin America

- The Brazilian government has launched initiatives to promote food safety and reduce waste, which is driving the adoption of aseptic packaging in the food and beverage sector.

- Companies like Amcor and Tetra Pak are expanding their operations in Latin America, focusing on developing cost-effective and sustainable packaging solutions tailored to local market needs.

North America

- The U.S. Food and Drug Administration (FDA) has implemented stricter regulations on food safety, prompting manufacturers to adopt aseptic packaging technologies to comply with these standards.

- Key players like Tetra Pak and SIG Combibloc are investing in innovative aseptic packaging solutions that enhance product shelf life and reduce environmental impact, reflecting a growing trend towards sustainability.

Middle East And Africa

- The Gulf Cooperation Council (GCC) countries are investing heavily in food processing infrastructure, which is expected to increase the demand for aseptic packaging solutions in the region.

- Local companies like Almarai are adopting advanced aseptic packaging technologies to extend the shelf life of dairy products, catering to the growing consumer demand for convenience.

Did You Know?

“Aseptic packaging can extend the shelf life of products without refrigeration for up to 12 months, making it a crucial technology for food preservation.” — International Dairy Foods Association

Segmental Market Size

The aseptic packaging sector is of great importance to the overall packaging industry, which is currently experiencing steady growth. It is driven by the increasing demand for longer-lasting and more convenient food and beverage products. The increasing awareness of food safety and the need for sustainable packaging solutions, which are gaining importance both among consumers and producers, are also contributing to this growth. The promotion of food safety standards by regulatory policies also enhances the sector’s position in the market. At present, aseptic packaging is in its mature stage, with companies such as Tetra Pak and SIG Combibloc leading the way with their innovations. This technology is widely used for dairy products, juices and ready-made meals. There are two important trends which will increase the growth of the sector: the demand for sustainable development and the impact of the flu pandemic on food safety. Advancing sterilization methods and smart packaging will continue to drive the sector’s evolution and ensure that aseptic packaging remains at the forefront of industry developments.

Future Outlook

The Aseptic Packaging Market is expected to register a CAGR of 6.97 percent from 2024 to 2032, rising from $63.42 billion to $108.75 billion. This growth is primarily due to the increasing demand for shelf-stable products, especially in the food and beverage industry, where consumers are increasingly demanding safe, convenient and long-lasting packaging solutions. As urbanization and hectic lifestyles continue to drive the purchase of aseptic products, the penetration of aseptic packaging is expected to rise, reaching approximately 30 percent of the total packaging market by 2032, compared to about 20 percent in 2024. Also, the development of new materials and sterilization methods, such as emulsions, is expected to increase the efficiency and effectiveness of aseptic packaging solutions. In addition, stringent food safety regulations and growing public awareness about the preservation of food will drive the growth of the market. The integration of smart packaging and the use of sustainable materials will also play an important role in shaping the future of the aseptic packaging market. Lastly, as companies focus more on the environment, the demand for eco-friendly aseptic packaging is expected to increase, in line with the global efforts to reduce plastic waste and promote the circular economy.

Leave a Comment