Growth of the Automotive Sector

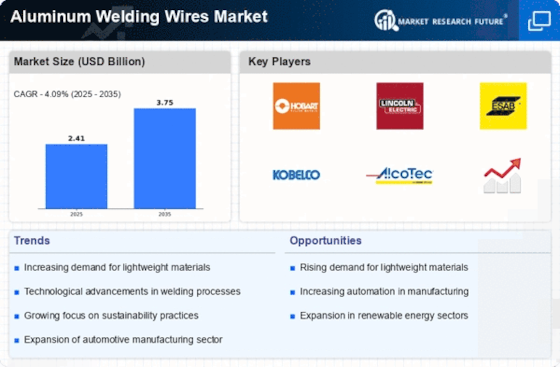

The Aluminum Welding Wires Market is closely linked to the growth of the automotive sector, which is increasingly utilizing aluminum for vehicle manufacturing. The automotive industry is shifting towards lightweight materials to enhance fuel efficiency and reduce emissions. As a result, the demand for aluminum welding wires is on the rise, as these materials are essential for assembling aluminum components. The market is projected to see a growth rate of approximately 4% in the coming years, driven by the automotive sector's transition towards more sustainable and efficient manufacturing practices. This trend not only supports the aluminum welding wires market but also aligns with broader environmental goals.

Rising Demand in Emerging Markets

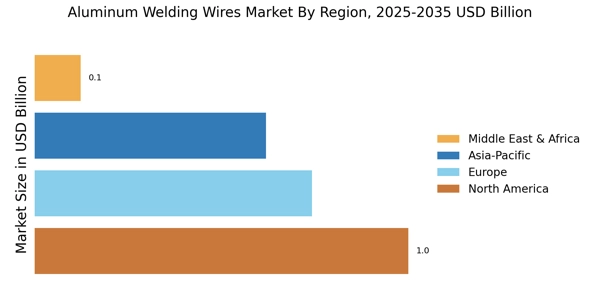

The Aluminum Welding Wires Market is benefiting from the rising demand in emerging markets, where industrialization and infrastructure development are accelerating. Countries in Asia and South America are investing heavily in construction and manufacturing sectors, leading to an increased need for aluminum welding wires. For instance, the construction of new transportation networks and urban infrastructure projects is driving the demand for high-quality welding materials. This trend is expected to contribute to a significant market expansion, with estimates suggesting a growth rate of around 6% in these regions over the next five years. The increasing adoption of aluminum in various applications further supports this demand.

Technological Advancements in Welding Techniques

The Aluminum Welding Wires Market is experiencing a notable transformation due to advancements in welding technologies. Innovations such as laser welding and friction stir welding are enhancing the efficiency and quality of aluminum welding processes. These technologies not only improve the speed of operations but also reduce the heat-affected zones, which is crucial for maintaining the integrity of aluminum materials. As a result, manufacturers are increasingly adopting these advanced techniques, leading to a surge in demand for specialized aluminum welding wires. The market is projected to grow at a compound annual growth rate of approximately 5% over the next few years, driven by these technological improvements.

Increased Investment in Infrastructure Development

The Aluminum Welding Wires Market is poised for growth due to increased investment in infrastructure development across various regions. Governments are allocating substantial budgets for the construction of roads, bridges, and public facilities, which necessitates the use of aluminum welding wires for structural integrity and durability. This trend is particularly pronounced in regions undergoing rapid urbanization, where the demand for robust construction materials is surging. Analysts predict that this investment will lead to a market growth rate of around 5% over the next few years, as the need for reliable and high-quality welding solutions becomes paramount in infrastructure projects.

Sustainability Initiatives and Eco-Friendly Practices

The Aluminum Welding Wires Market is witnessing a shift towards sustainability, as manufacturers and consumers alike prioritize eco-friendly practices. The increasing emphasis on reducing carbon footprints and utilizing recyclable materials is prompting companies to develop aluminum welding wires that align with these sustainability goals. This trend is particularly evident in industries such as automotive and construction, where there is a growing demand for lightweight and recyclable materials. As a result, the market for aluminum welding wires is expected to expand, with a projected increase in demand for sustainable products. This shift not only enhances brand reputation but also meets regulatory requirements, further driving market growth.