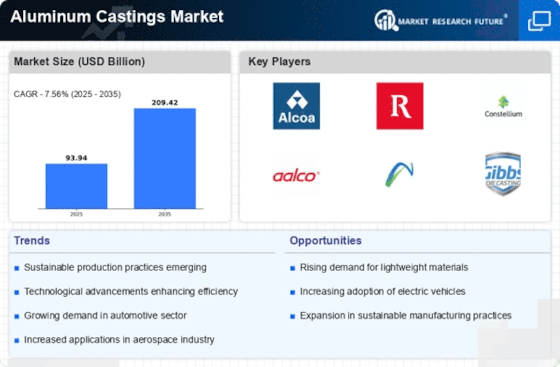

Top Industry Leaders in the Aluminum Castings Market

Aluminum castings, lightweight yet robust, play a crucial role in shaping our world, from the sleek frames of smartphones to the engines powering airplanes. This multi-billion dollar market is a dynamic arena where diverse players vie for dominance. Let's embark on a deep dive into the competitive landscape of aluminum castings, exploring the key trends, influential factors, recent news, and current developments driving this exciting space.

Aluminum castings, lightweight yet robust, play a crucial role in shaping our world, from the sleek frames of smartphones to the engines powering airplanes. This multi-billion dollar market is a dynamic arena where diverse players vie for dominance. Let's embark on a deep dive into the competitive landscape of aluminum castings, exploring the key trends, influential factors, recent news, and current developments driving this exciting space.

Market Leaders and Strategies:

-

Global Giants: Industrial powerhouses like China Nonferrous Metals Holding Group, Nemak (Mexico), and UACJ Corporation (Japan) leverage their production capacities, extensive global reach, and diverse casting technologies to cater to a wide range of industries. They focus on cost-efficiency, standardization, and vertical integration. -

Regional Champions: Companies like EDAG Engineering Group (Germany), Tech Castings Corp. (US), and Tongling Non-Ferrous Metals Group (China) excel in specific regional markets and niche applications. They offer customized solutions, build strong relationships with local players, and adapt to regional regulations. -

Innovation Trailblazers: The rise of advanced technologies like additive manufacturing and lightweighting has spawned a new breed of players like Stratasys (US) and Alcoa Corporation (US) focused on innovative casting techniques and high-performance alloys. They cater to the growing demand for cutting-edge applications and sustainability solutions.

Key Strategies Fueling Market Share:

-

Technology Prowess: Investing in R&D to develop next-generation casting technologies like low-pressure casting, vacuum casting, and additive manufacturing keeps players ahead of the curve. Continuous improvement in production efficiency and reduction in waste are crucial. -

Sustainability Champions: Integrating eco-friendly practices throughout the value chain, from sourcing recycled aluminum to adopting energy-efficient processes, resonates with both consumers and businesses. Lightweighting solutions to reduce fuel consumption and carbon footprint offer a competitive edge. -

Compliance and Certifications: Stringent regulations like REACH in Europe and TSCA in the US necessitate meticulous adherence to safety and environmental standards. Obtaining relevant certifications opens doors to lucrative markets and fosters trust with stakeholders. -

Industry Collaborations: Partnering with automotive manufacturers, aerospace companies, and engineering firms fosters knowledge sharing, co-development opportunities, and market access.

Key Companies in the Aluminum Castings market include

- Alcast Technologies Ltd. (Canada)

- Alcoa Corporation (USA)

- Aluminum Corporation of China Limited (China)

- Arconic Inc. (USA)

- Dynacast Charlotte (USA)

- Endurance Technologies (India)

- Gibbs Die Casting Corp (USA)

- Kaiser Aluminum (USA)

- Martinrea Honsel (Germany)

- Nemak S.A.B. de C.V. (Mexico)

- Rio Tinto (UK)

- Rockman Industries Ltd. (India)

- Ryobi Limited (Japan).

Recent Developments

December 2021, TRIMET Aluminium SE began manufacturing aluminum sows in November with the commissioning of a new aluminum casting machine at its Hamburg (Germany) location. The aluminum smelter can now cast approximately 45,000 metric tonnes of aluminum produced via electrolysis each year, nearly doubling its capacity as a result of the investment. Apart from the increased productivity, the new casting machine is a significant improvement in terms of worker health and safety: The entire process is automated, from casting, skimming, and identifying the sows to weighing and putting them on a conveyor belt. Thus, robots accomplish tasks that previously required manual labor. The new machine is a casting carousel equipped with 18 molds. Every two hours, it can cast 18 metal sows weighing 780 kilos apiece. The new technical standard ensures that products are continuously of excellent quality.

In March 2020, Martinrea International Inc., which manufactures propulsion systems as well as lightweight structures used in cars like those produced by Tesla Motors Inc., acquired Metalsa S.A de C.V.'s structural components business segment; six plants were added including facilities located in Germany (two), Mexico (two), South Africa (one), China (two) with one more planned; it is anticipated that these moves will help solidify Martinrea's position within Europe while also broadening its customer base globally.