Increasing Demand for Aircraft Safety

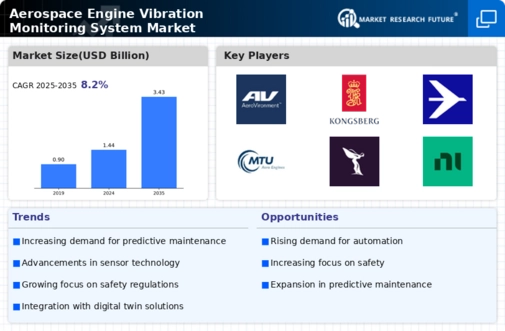

The aerospace engine vibration monitoring system Market is experiencing a surge in demand driven by the heightened focus on aircraft safety. As aviation authorities and manufacturers prioritize safety protocols, the implementation of advanced monitoring systems becomes essential. The market is projected to grow at a compound annual growth rate of approximately 7% over the next five years, reflecting the industry's commitment to reducing mechanical failures and enhancing passenger safety. This trend is further supported by the increasing number of air travel passengers, which necessitates the deployment of reliable monitoring systems to ensure operational integrity. Consequently, the Aerospace Engine Vibration Monitoring System Market is likely to witness significant investments aimed at developing innovative solutions that can effectively monitor engine performance and detect anomalies in real-time.

Growing Focus on Predictive Maintenance

The Aerospace Engine Vibration Monitoring System Market is witnessing a growing emphasis on predictive maintenance strategies. Airlines and operators are increasingly recognizing the value of utilizing vibration monitoring systems to predict potential engine failures before they occur. This proactive approach not only minimizes downtime but also significantly reduces maintenance costs. According to industry estimates, predictive maintenance can lower maintenance expenses by approximately 30%, making it an attractive option for operators. As the aviation sector continues to evolve, the demand for systems that facilitate predictive maintenance is expected to rise. Consequently, the Aerospace Engine Vibration Monitoring System Market is likely to expand as stakeholders seek to implement solutions that enhance operational efficiency and reliability.

Expansion of Aerospace Manufacturing Sector

The Aerospace Engine Vibration Monitoring System Market is poised for growth due to the expansion of the aerospace manufacturing sector. As new aircraft models are developed and existing fleets are upgraded, the need for advanced monitoring systems becomes increasingly critical. The aerospace manufacturing sector is projected to grow at a rate of 5% annually, driven by innovations in aircraft design and technology. This growth is likely to create a substantial demand for vibration monitoring systems that can ensure the reliability and safety of new engines. Furthermore, as manufacturers strive to meet the rising demand for air travel, the Aerospace Engine Vibration Monitoring System Market is expected to benefit from increased investments in research and development, leading to the introduction of cutting-edge monitoring solutions.

Regulatory Pressures and Compliance Standards

The Aerospace Engine Vibration Monitoring System Market is significantly influenced by regulatory pressures and compliance standards imposed by aviation authorities. Stricter regulations regarding engine performance and safety are compelling manufacturers to adopt advanced monitoring systems. For instance, the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established guidelines that necessitate the implementation of vibration monitoring to ensure compliance. This regulatory landscape is expected to propel the market forward, as companies invest in technologies that meet these stringent requirements. The Aerospace Engine Vibration Monitoring System Market is thus likely to see a rise in demand for systems that not only comply with existing regulations but also anticipate future standards, ensuring long-term operational viability.

Technological Innovations in Monitoring Systems

Technological advancements play a pivotal role in shaping the Aerospace Engine Vibration Monitoring System Market. The integration of artificial intelligence and machine learning algorithms into monitoring systems enhances their predictive capabilities, allowing for more accurate assessments of engine health. Recent developments indicate that systems equipped with these technologies can reduce maintenance costs by up to 20%, thereby appealing to operators seeking cost-effective solutions. Furthermore, the advent of Internet of Things (IoT) devices facilitates real-time data transmission, enabling proactive maintenance strategies. As these innovations continue to evolve, the Aerospace Engine Vibration Monitoring System Market is expected to expand, driven by the need for more sophisticated and efficient monitoring solutions that can adapt to the complexities of modern aerospace engines.