Growth in Automotive Industry

The automotive sector plays a crucial role in shaping the Global Adhesive Resin Market Industry. With the increasing production of vehicles, there is a rising need for adhesives that can withstand high temperatures and provide durable bonding. Adhesive resins are extensively used in vehicle assembly, particularly in bonding components like windshields and interior parts. The automotive industry's shift towards lightweight materials further enhances the demand for advanced adhesive solutions. This trend is expected to contribute significantly to the market's growth, with projections indicating a market value of 87.8 USD Billion by 2035.

Expansion of Packaging Industry

The packaging industry significantly influences the Global Adhesive Resin Market Industry, particularly with the rise of e-commerce and online retail. Adhesive resins are essential in creating durable and efficient packaging solutions that ensure product safety during transit. The demand for innovative packaging materials, including flexible and rigid containers, drives the need for high-performance adhesive solutions. As the packaging sector continues to grow, propelled by changing consumer behaviors and preferences, the adhesive resin market is poised for substantial growth. This trend underscores the interconnectedness of various industries and their collective impact on adhesive resin demand.

Market Trends and Growth Projections

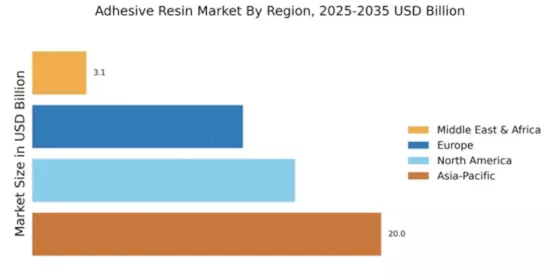

The Global Adhesive Resin Market Industry is characterized by dynamic trends and growth projections. The market is anticipated to reach a value of 50.2 USD Billion in 2024, with expectations to expand to 87.8 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate of 5.21% from 2025 to 2035. Various factors, including technological advancements, increasing demand from diverse sectors, and a shift towards sustainable products, contribute to this optimistic outlook. The interplay of these elements indicates a vibrant future for the adhesive resin market, reflecting its essential role in numerous applications.

Rising Demand in Construction Sector

The Global Adhesive Resin Market Industry experiences a notable surge in demand driven by the construction sector. As urbanization accelerates, the need for efficient bonding solutions in building materials becomes paramount. Adhesive resins are increasingly utilized in applications such as flooring, roofing, and insulation. This trend is reflected in the projected market value of 50.2 USD Billion in 2024, indicating a robust growth trajectory. The construction industry's expansion, particularly in emerging economies, further propels the demand for adhesive resins, suggesting a sustained growth pattern in the coming years.

Technological Advancements in Adhesive Formulations

Innovations in adhesive formulations significantly influence the Global Adhesive Resin Market Industry. The development of high-performance resins that offer enhanced bonding capabilities and environmental sustainability is gaining traction. For instance, bio-based adhesive resins are emerging as viable alternatives to traditional petroleum-based products. These advancements not only cater to the growing consumer preference for eco-friendly solutions but also align with regulatory trends favoring sustainable materials. As a result, the market is expected to witness a compound annual growth rate of 5.21% from 2025 to 2035, driven by these technological innovations.

Increasing Consumer Preference for Eco-Friendly Products

Consumer awareness regarding environmental sustainability is driving the Global Adhesive Resin Market Industry towards eco-friendly alternatives. As consumers increasingly seek products that minimize environmental impact, manufacturers are responding by developing bio-based and recyclable adhesive resins. This shift not only meets consumer demand but also aligns with global sustainability goals. The growing emphasis on green building practices and sustainable manufacturing processes further supports this trend. Consequently, the market is likely to expand as companies innovate to create environmentally responsible adhesive solutions, reflecting a broader commitment to sustainability in various industries.