Additive Manufacturing Machine Size

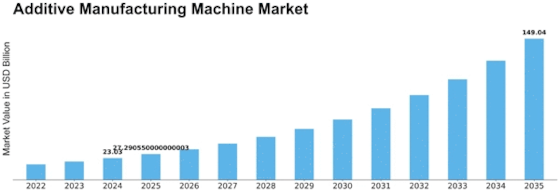

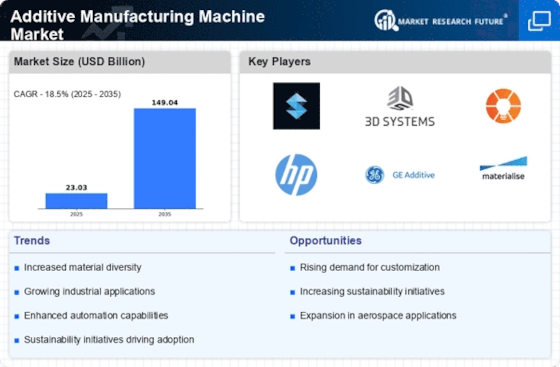

Additive Manufacturing Machine Market Growth Projections and Opportunities

The market dynamics of the additive manufacturing machine, commonly known as 3D printing, have undergone significant evolution in recent years. The continuous innovation and development of 3D printing technologies are one of the main drivers shaping these dynamics. The introduction of new and improved additive manufacturing machines to the market is fueled by researchers and engineers who are constantly pushing the boundaries of what can be done. These innovative machines not only make 3D printing more accurate and faster but also enable a wider variety of materials to be used, thus opening doors for diverse industries such as aerospace, healthcare, automotive, and consumer goods. The application base of additive manufacturing machines has recently been another key determinant in market dynamics. Over time, 3D printing has gone beyond mere prototyping to being a mainstream production process. Business efficiency, as well as cost-effectiveness, matter so much for businesses where additive manufacturing machines come with enormous benefits. Cost savings and streamlined operations are enhanced through complex geometries with minimal material wastage, rapid prototyping, and on-demand production, among others. As a consequence, companies are appreciating that there is value in including 3D printing in their production processes, leading to the general growth of additive manufacturing machine markets. Regulatory influences over global additive manufacturing machine markets also play a role when it comes to global additive manufacturing machine markets together with standards. Guidelines and regulations implemented by governments and industry bodies ensure the safety and quality assurance of products made through 3D printing technology. Additionally, the competitive landscape within the additive manufacturing machine market is characterized by established firms versus startups offering innovations. Equally important is the geographical distributional aspect, which contributes significantly to its dynamics concerning how it happens worldwide across different regions where various countries are situated. Generally, therefore, based on technological advancement, widening areas whereby they are applied, cost-effectiveness factors considered in producing them, and regulatory implications put across against the backdrop of heavy competition, these dynamisms characterize them.

Leave a Comment