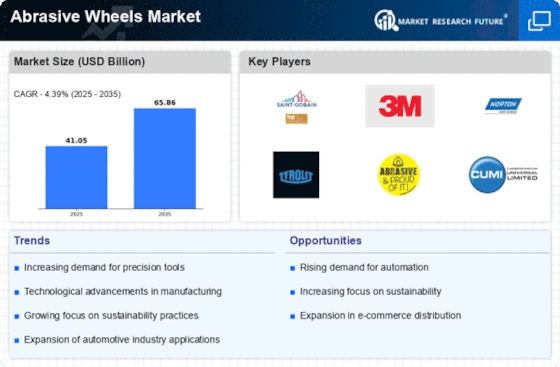

Growth in Construction Activities

The construction industry is currently undergoing a robust expansion, which is positively impacting the Abrasive Wheels Market. With the increasing number of infrastructure projects and residential developments, there is a heightened requirement for cutting, grinding, and finishing tools. The demand for abrasive wheels in construction applications is projected to grow at a rate of around 6% per year, reflecting the industry's recovery and growth trajectory. This growth is likely to be supported by government initiatives aimed at improving infrastructure, which in turn drives the need for high-quality abrasive products that can withstand rigorous use in construction environments.

Expansion of Metalworking Industry

The metalworking industry is currently experiencing substantial growth, which is significantly impacting the Abrasive Wheels Market. As manufacturing processes become more sophisticated, the demand for high-quality abrasive wheels for metal cutting and finishing applications is on the rise. The metalworking sector is projected to grow at a rate of approximately 5% per year, driven by advancements in technology and increased production capacities. This growth is likely to be accompanied by a shift towards more specialized abrasive products that cater to specific metalworking needs, thereby enhancing the overall efficiency and effectiveness of manufacturing operations.

Rising Demand in Automotive Sector

The automotive sector is experiencing a notable surge in demand for abrasive wheels, driven by the increasing production of vehicles and the need for precision in manufacturing processes. As manufacturers strive for higher efficiency and quality, the Abrasive Wheels Market is witnessing a corresponding rise in the adoption of advanced abrasive products. In 2025, the automotive industry is projected to account for a significant share of the abrasive wheels market, with estimates suggesting a growth rate of approximately 5% annually. This trend is likely to be fueled by the ongoing innovations in vehicle design and the need for enhanced performance, thereby propelling the demand for specialized abrasive wheels tailored for automotive applications.

Increasing Focus on Safety Standards

The emphasis on safety standards in industrial operations is becoming increasingly pronounced, influencing the Abrasive Wheels Market. Regulatory bodies are mandating stricter safety protocols, which necessitate the use of high-quality abrasive wheels that meet specific safety criteria. This trend is likely to drive manufacturers to invest in better quality control and product development, ensuring compliance with safety regulations. As a result, the market for safety-compliant abrasive wheels is expected to grow, with estimates suggesting a potential increase of around 4% annually. This focus on safety not only enhances worker protection but also promotes the adoption of superior abrasive products across various industries.

Technological Innovations in Abrasive Products

Technological advancements are playing a pivotal role in shaping the Abrasive Wheels Market. Innovations such as the development of diamond and CBN (Cubic Boron Nitride) wheels are enhancing the performance and lifespan of abrasive products. These advancements are likely to lead to increased efficiency in manufacturing processes, as they allow for faster cutting and grinding with reduced wear. The market for these high-performance abrasive wheels is expected to expand significantly, with projections indicating a growth rate of approximately 7% over the next few years. As industries seek to optimize their operations, the demand for technologically advanced abrasive wheels is anticipated to rise, further driving the market.