Sustainability Initiatives

The 3D Ceramic Printer Market is increasingly influenced by sustainability initiatives that promote eco-friendly manufacturing processes. As industries face mounting pressure to reduce their carbon footprints, 3D printing offers a viable solution by minimizing waste and utilizing sustainable materials. The ability to produce complex geometries with less material waste aligns with the global push for sustainable practices. Additionally, many manufacturers are exploring the use of recycled ceramics in their printing processes, further enhancing the environmental benefits. This shift towards sustainability is not only appealing to consumers but is also becoming a regulatory requirement in many regions, thereby driving the demand for 3D ceramic printers.

Expansion of Application Areas

The 3D Ceramic Printer Market is expanding into new application areas, which is a key driver of its growth. Beyond traditional uses in pottery and decorative items, 3D ceramic printing is finding applications in sectors such as biomedical engineering, where custom implants and prosthetics are being developed. The ability to create complex, patient-specific designs is revolutionizing the healthcare industry. Furthermore, the construction sector is exploring the use of 3D printed ceramics for building components, which could lead to more efficient construction methods. This diversification of applications is likely to attract new investments and drive further innovation within the 3D ceramic printer market.

Cost Efficiency and Production Speed

The 3D Ceramic Printer Market is benefiting from advancements that enhance cost efficiency and production speed. As the technology matures, the costs associated with 3D printing are decreasing, making it a more accessible option for manufacturers. The ability to produce complex parts in a single print run reduces the need for multiple manufacturing processes, thereby lowering overall production costs. Additionally, the speed of production has improved significantly, with some printers capable of producing high-quality ceramic parts in a matter of hours. This efficiency is particularly appealing to industries that require rapid prototyping and short production runs, further driving the adoption of 3D ceramic printing technologies.

Customization Demand in Various Industries

The 3D Ceramic Printer Market is witnessing a surge in demand for customization across various sectors. Industries such as architecture, art, and consumer goods are increasingly seeking tailored solutions that traditional manufacturing methods cannot provide. The ability to create unique, bespoke ceramic products through 3D printing allows companies to differentiate themselves in competitive markets. Recent studies indicate that approximately 40% of manufacturers are investing in 3D printing technologies to meet the growing consumer demand for personalized products. This trend is expected to continue, as consumers increasingly value individuality and uniqueness in their purchases, further propelling the growth of the 3D ceramic printer market.

Technological Advancements in 3D Ceramic Printing

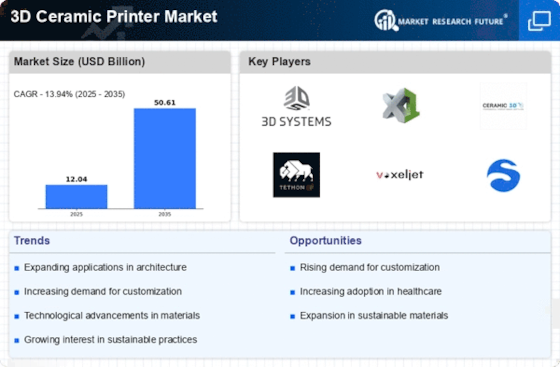

The 3D Ceramic Printer Market is experiencing rapid technological advancements that enhance printing capabilities and efficiency. Innovations in materials science, such as the development of new ceramic composites, are enabling printers to produce more intricate designs with improved mechanical properties. Furthermore, advancements in software and hardware integration are streamlining the printing process, reducing production times significantly. According to recent data, the market for 3D ceramic printers is projected to grow at a compound annual growth rate of approximately 25% over the next five years. This growth is largely driven by the increasing adoption of 3D printing technologies in various sectors, including aerospace, automotive, and healthcare, where precision and customization are paramount.